Synopsis

- Visual piping system surveys and piping schematic updates reveal critical safety and efficiency concerns in hospital systems.

- Common issues identified include mislabeling, improper backflow devices, and outdated or unnecessary piping.

- Proactive updates to piping documentation can prevent incidents and improve operational efficiency.

The Practical Guide to Piping Schematics

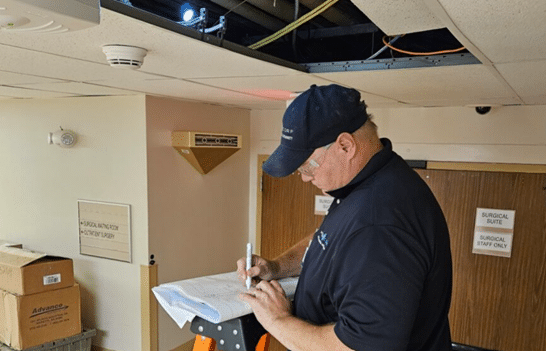

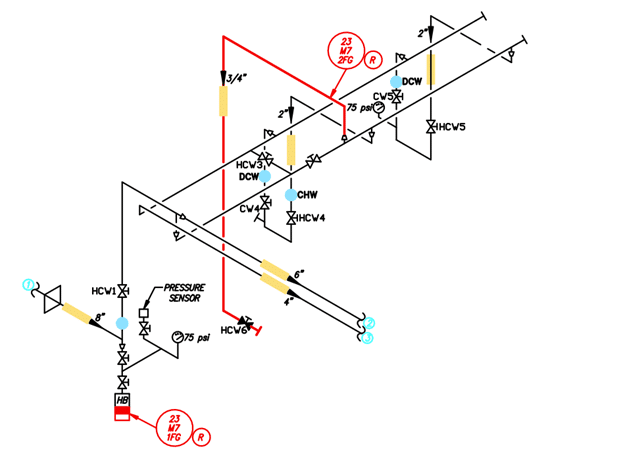

Conducting a thorough visual survey and updating piping schematics may appear to be a steep climb to tackle, but the findings can result in a significant win and incident prevention return on investment. Updating hospital piping schematics to reflect actual conditions often reveals a host of concerns that can compromise both system safety and operational efficiency. Piping system visual surveys frequently identify mislabeling, improper backflow prevention devices, and outdated or unnecessary piping installations. Below are 10 concerning findings from recent hospital piping system surveys conducted by HydroCorp for our client healthcare networks that emphasize the importance of proactive updates to existing piping system documentation.

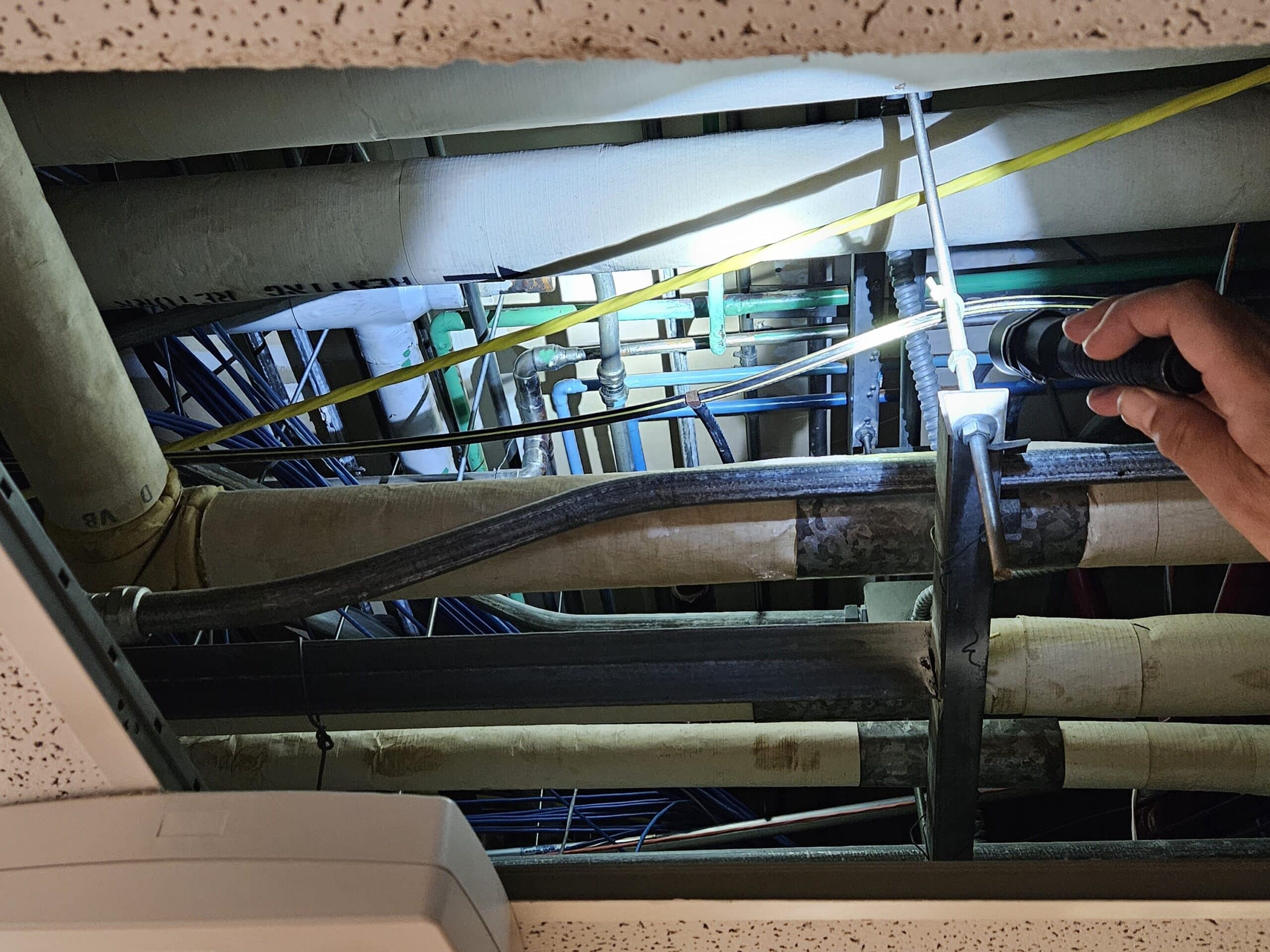

1. Potable Water and Domestic Hot Water Piping Mislabeled

One of the most common issues we encounter is the mislabeling of potable water and domestic hot water lines as “PERIMETER HEAT SUPPLY/RETURN”. This labeling error can create confusion and delay responses during emergencies or routine maintenance. We recommend immediate relabeling to “POTABLE WATER” and “DOMESTIC HOT WATER” to ensure proper identification and system integrity.

2. Unused Domestic Hot Water Piping

During several surveys, we found domestic hot water piping that was no longer in use but still connected to the system. This poses unnecessary risks, including potential contamination. The unused piping should be disconnected and capped to maintain system hygiene and prevent any future issues.

3. Mislabeling of Non-Potable Water as Domestic Cold Water

Non-potable water piping was frequently found mislabeled as “DOMESTIC COLD WATER” in multiple areas. This can lead to dangerous cross-connections and potential health hazards if non-potable water is mistakenly used for drinking or cleaning. Proper relabeling to “NON-POTABLE WATER” is critical to avoid any mix-ups.

4. Lab Equipment Requires Correct Backflow Prevention

In one instance, lab equipment was protected by an inappropriate double check valve. To ensure proper backflow prevention in lab environments, where contaminants can easily enter the water system, the existing double check valve should be replaced with a Reduced Pressure Zone (RPZ) backflow preventer.

5. Reverse Osmosis (R.O.) System Backflow Protection

The supply to Reverse Osmosis (RO) water make-up systems requires proper protection. All too often, we find incorrect assemblies that are insufficient to protect the water, like a double check valve. This should be replaced with an RPZ to meet regulatory requirements and ensure backflow protection, especially in critical systems like RO water supply.

6. Unnecessary RPZ on Eyewash Stations

During our surveys, we often discover unnecessary devices as well. In one instance, our surveyor discovered an RPZ supplying multiple eyewash stations. The RPZ is not required in this configuration and should be removed. When removing the RPZ, we recommend installing Hose Bibb Vacuum Breakers (HBVB) on any connected hose bibbs or replumbing the eyewashes to a dedicated potable water supply to eliminate unnecessary cross-connection risk.

7. Replace Atmospheric Vacuum Breaker with Pressure Vacuum Breaker

For hand sprayers connected to the water system, we often find Atmospheric Vacuum Breakers (AVB) in use. These should be replaced with a more reliable Pressure Vacuum Breaker (PVB), especially where valves are installed downstream of the backflow device, to prevent any contamination.

8. Lawn Irrigation System Backflow Prevention

A recurring concern is the backflow prevention on lawn irrigation systems. Due to the elevation of exposed sprinkler heads, a more robust solution is required. We recommend verifying the current assembly and installing an RPZ (Reduced Pressure Zone Backflow Preventer) to ensure proper protection against backflow.

9. Janitor’s Sink Lacks Proper Backflow Prevention

When checking janitorial closets, we repeatedly find janitor’s sinks that are missing an essential Hose Bibb Vacuum Breaker (HBVB). This is a straightforward yet critical fix to prevent backflow into the potable water system when hoses are connected.

10. Boiler System Lacking Proper Backflow Prevention

A boiler system was found with only a double check valve, which is insufficient for this high-risk application. Replacing it with an RPZ will offer better backflow protection in compliance with safety standards.

Updating Hospital Piping Systems for Safety and Compliance

These findings underscore the need for proactive hospital piping surveys to identify and address potential hazards. Mislabeled pipes, outdated backflow devices, and unused piping can lead to severe safety concerns, regulatory non-compliance, and costly operational inefficiencies.

HydroCorp specializes in hospital piping surveys and reverse-engineering piping systems to ensure safety and compliance. By updating your piping schematics, your facility can improve both patient safety and regulatory compliance while reducing maintenance costs.

Need help with your facility’s piping systems? Contact HydroCorp today to schedule a professional survey and get your piping schematics up to date!