From Medical Gas Systems to Potable Water Systems, piping schematics play a critical role in understanding the layout and functioning of a hospital’s piping systems. These diagrams are visual representations of the facility’s plumbing infrastructure, providing essential access for maintenance, operational, and emergency response purposes. In a knowledge capture process, it’s essential to include piping schematics to complement the documentation.

“The secrets to a smoothly running facility are often hidden in the vault of legacy knowledge”

.

.

The Practical Guide to Piping Schematics

Legacy Knowledge Preservation Checklist

By following these 10 steps below, you can create a robust knowledge base that benefits current and future staff, ultimately enhancing patient care and facility efficiency.

Step 1: Identify Key Personnel

Identify the experienced technicians who possess essential knowledge about the hospital’s piping systems and valve locations. They will be your primary sources of information.

Step 2: Document Existing Information

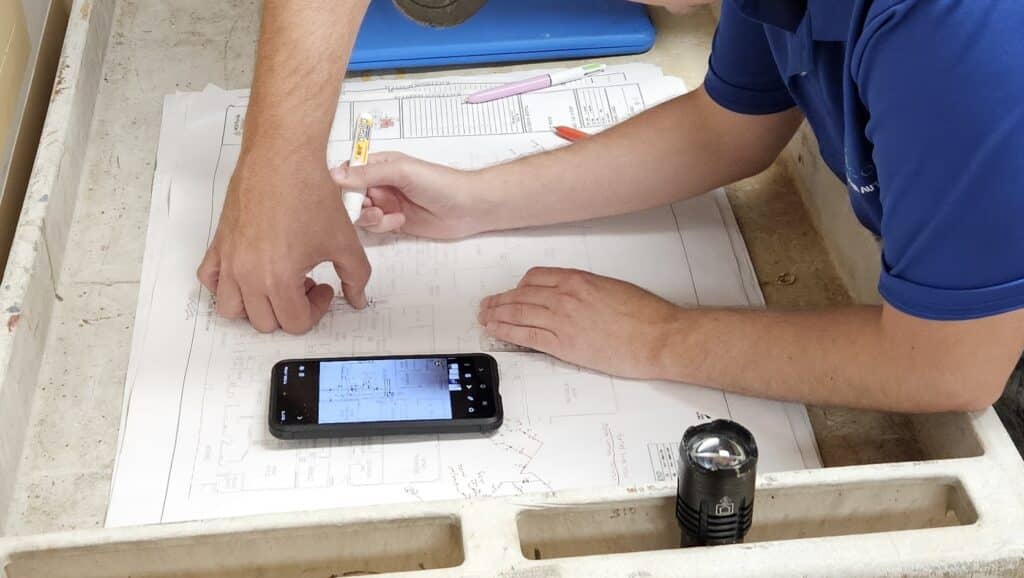

Review any existing documentation, blueprints, or digital records related to the facility’s piping systems and valve locations. This will serve as a foundation for your knowledge capture process.

Step 3: Conduct Interviews

Schedule interviews with the identified technicians. Prepare a list of questions to extract detailed information about system configurations, valve types, maintenance procedures, and any critical insights they can provide.

Step 4: Create a Standardized Format

Develop a standardized format or template for documenting the captured knowledge. This format should be easy to understand and organized for easy retrieval.

Step 5: Document Piping System Details

Begin documenting the specifics of each piping system within the facility. Include information on pipe materials, diameters, routing, and connections. Photographs can also be helpful.

Step 6: Capture Valve Location Details

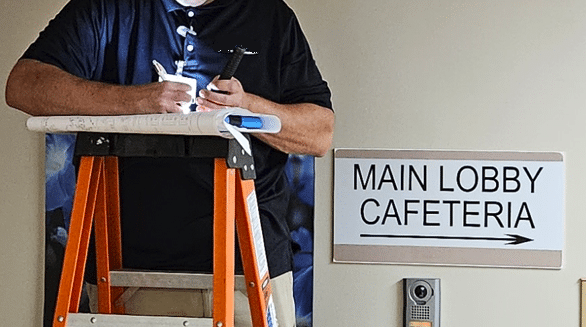

Record the location of all valves in the facility, including details such as valve types, sizes, functions, and any unique features. Digital mapping tools can be valuable for this step.

Step 7: Maintenance Procedures

Gather information about maintenance procedures, schedules, and any historical issues related to the piping systems and valves. Include tips and best practices from experienced technicians.

Step 8: Organize the Information

Organize the captured information into a centralized knowledge repository. This can be a physical binder or a digital database, making it accessible to all relevant staff.

Step 9: Create Training Materials

Based on the captured knowledge, develop training materials for new technicians and staff to ensure they understand the hospital’s piping systems and valve locations.

Step 10: Regularly Update

Legacy knowledge is not static. Implement a system for regular updates to ensure that the captured information remains current as the facility evolves.

.

.

Cost of not documenting Legacy Knowledge

The cost impact of not capturing legacy knowledge of hospital piping and valve details can be significant and multifaceted. Without access to comprehensive information about the facility’s plumbing systems and valve locations, hospital maintenance and operations staff face increased challenges and expenses.

First and foremost, it leads to inefficiencies in routine maintenance and repairs, as technicians may struggle to locate and address issues promptly, resulting in extended downtime and increased labor costs. Moreover, the lack of knowledge about the systems’ history and unique characteristics can lead to higher risks of costly emergency repairs and replacements. Inefficient use of resources, increased energy consumption, and potential safety hazards can also escalate operating costs. Furthermore, compliance with regulatory standards becomes more challenging, which can result in costly fines and penalties. In sum, the failure to capture legacy knowledge can have a direct and lasting financial impact on a hospital’s budget, underscoring the necessity of a systematic knowledge transfer process for these critical systems.

.

Call to Action Summary:

Capturing legacy knowledge from hospital facility technicians about piping systems and valve locations is essential for maintaining the integrity and functionality of healthcare facilities. There are many benefits to

Transferring Legacy Knowledge to accurate schematics can:

- Improve Visual Representation: Piping schematics offer a visual overview of the piping network, helping technicians quickly grasp the system’s complexity.

- Be the Reliable Daily Road Map: They detail the layout, connections, and flow paths of pipes, valves, and components, making it easier to locate and identify specific elements.

- Speed up Troubleshooting: Piping schematics aid in troubleshooting by visually identifying potential issues, such as blockages, leaks, or malfunctioning valves.

- Assist in Planning and Preventive Maintenance: With schematics, maintenance procedures can be accurately planned, reducing the risk of system failures and ensuring consistent water flow and supply.

- Be Part of Staff Training Methods: Piping schematics are invaluable training tools for new technicians, as they provide a clear visual reference for understanding the facility’s plumbing infrastructure.