Key Points:

- There are a number of key plumbing systems that help hospitals and other large scale healthcare facilities run safely and smoothly

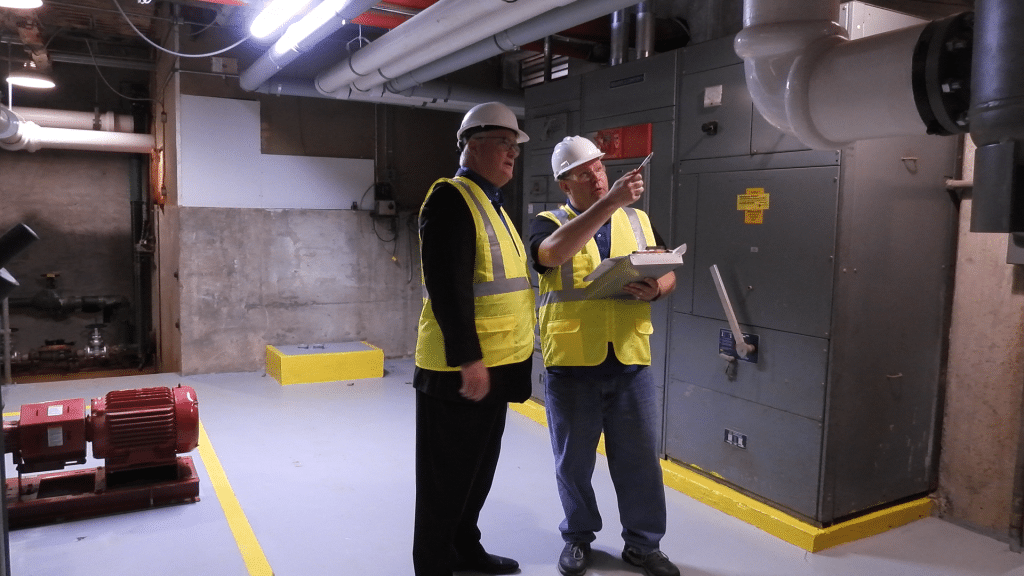

- Surveying these systems and updating their schematics is necessary but time-consuming and expensive

- Prioritizing the systems and moving through each one methodically will yield a series of benefits to the hospital or healthcare facility both in the short and long term

The Practical Guide to Piping Schematics

Prioritizing and evaluating which hospital plumbing systems require detailed visual surveys and the creation of accurate schematics is crucial for maintaining both safety and operational efficiency. Facility and maintenance directors must consider several factors when deciding which systems to survey, including the complexity and criticality of the system, maintenance and upkeep requirements, potential for contamination and safety hazards, regulatory compliance, and the age and condition of the system. Systems that are integral to hospital operations, such as dialysis and sterilizer systems, should be prioritized due to their complexity and critical roles. Additionally, systems that require frequent maintenance, pose high contamination risks, and are subject to strict regulatory standards should be surveyed to ensure compliance and prevent hazards.

Understanding Hospital Plumbing Systems

Below is a list of common water-based systems in hospitals or other large healthcare facilities as well as their respective complexity, importance to safety, and difficulty of maintenance.

- Domestic Water Systems

- Complexity: Moderate complexity due to quality standards and regular monitoring.

- Safety: Regular testing for contaminants. Must ensure potable water quality.

- Maintenance: Frequent inspections for leaks and corrosion to prevent water damage and health risks.

- Dialysis Water Systems

- Complexity: High complexity because of the need for ultra-pure water and stringent safety requirements.

- Safety: Continuous monitoring for contaminants. Requires ultra-pure water to prevent patient infections.

- Maintenance: High-frequency filter replacements and water quality testing.

- Central Sterile and Laboratory Systems

- Complexity: High complexity due to the need for high purity and consistent quality.

- Safety: Prevent contamination; ensure proper disposal of hazardous materials.

- Maintenance: Routine sterilization and inspections; maintenance of backflow preventers.

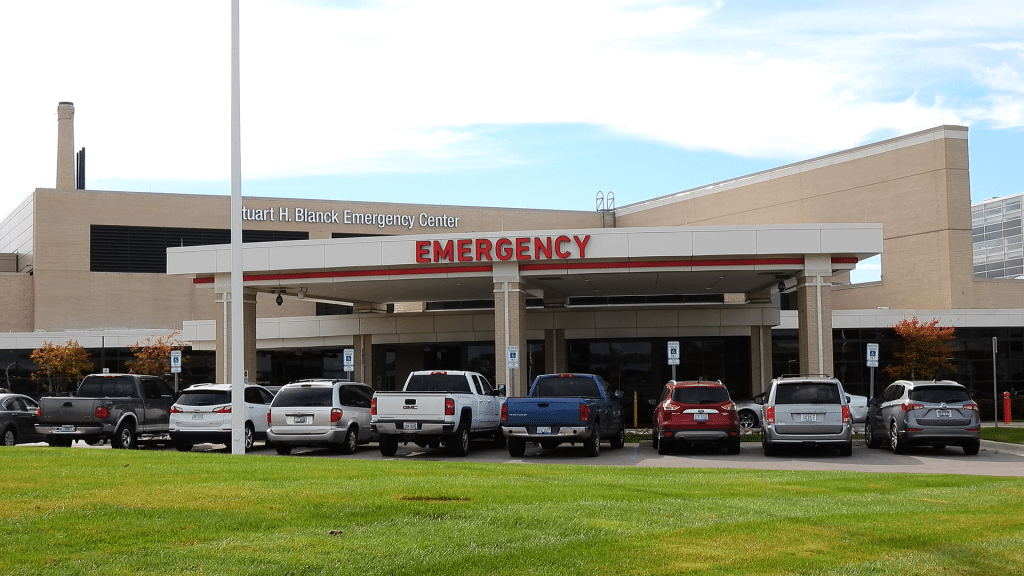

- Emergency Plumbing Systems

- Complexity: Moderate to high complexity for ensuring reliability and rapid deployment in crises.

- Safety: Must remain operational during emergencies. Critical for fire suppression and eyewash stations.

- Maintenance: Regular checks to ensure functionality during emergencies.

- Wastewater Systems

- Complexity: High complexity because of sophisticated treatment processes and environmental protection measures.

- Safety: Handles both biological and chemical waste. Prevent leaks and contamination of public water supplies.

- Maintenance: Frequent inspections and maintenance of traps and vents to prevent blockages and wastewater backflows.

Financial and Risk Reduction Benefits

Financially, hospitals benefit from reduced downtime and operational disruptions when plumbing systems are accurately mapped and regularly maintained. Accurate schematics allow for quicker repairs and maintenance, minimizing disruptions to hospital operations. From a risk reduction perspective, properly labeled pipes and documented valve locations improve emergency response times and ensure compliance with health and safety regulations. This proactive approach also extends the lifespan of plumbing systems and reduces the likelihood of costly emergency repairs. Furthermore, maintaining high water quality and infection control in critical areas like dialysis and sterilization units enhances patient safety and care quality.

- Reduced Downtime and Operational Disruptions

- Accurate schematics facilitate quicker repairs and maintenance, minimizing disruptions and maintaining hospital operations.

- Enhanced Safety and Compliance

- Properly labeled pipes and documented valve locations improve emergency response times and ensure compliance with health and safety regulations.

- Preventive Maintenance and Cost Savings

- Detailed surveys enable proactive maintenance, reducing the likelihood of costly emergency repairs and extending the lifespan of plumbing systems.

- Improved Water Quality and Infection Control

- Ensuring correct piping and connection safety devices maintain water quality, crucial for patient care areas like dialysis and sterilization units.

- Efficient Resource Management

- By keeping thorough and detailed records of theses systems, resources such as budget and manpower can be managed efficiently and precisely.

Hospital piping systems encompass a variety of types, each with unique differences and challenges for safety and maintenance. By conducting detailed surveys and creating accurate schematics for these systems, hospitals can achieve better safety, compliance, and cost-efficiency. Operational efficiency is improved through minimized downtime and expedited repairs. Regulatory compliance is ensured as all systems meet health and safety standards. Cost savings are realized through reduced emergency repair costs and extended lifespan of plumbing infrastructure. Enhanced safety is achieved by improving emergency response capabilities with accurate valve locations and proper pipe labeling. Ultimately, these measures contribute to a safer and more efficient hospital environment, benefiting both patients and staff.

Five Deciding Factors

- System Complexity and Criticality

- Prioritize systems integral to hospital operations, like dialysis and sterilizer systems, due to their complex setups and critical roles.

- Maintenance and Upkeep Requirements

- Systems requiring frequent maintenance (e.g., emergency plumbing systems) should be prioritized to ensure compliance with safety standards and minimize downtime.

- Potential for Contamination and Safety Hazards

- Systems with high contamination risks, such as laboratory and central sterile systems, need accurate schematics to prevent and manage potential hazards effectively.

- Regulatory Compliance

- Ensure systems like domestic hot water and emergency plumbing meet regulatory standards, necessitating detailed surveys to verify compliance.

- System Age and Condition

- Older systems or those with known issues should be surveyed first to assess current conditions and plan necessary upgrades or repairs.

Accurate piping maps assist in resource planning, optimizing water and energy use, and potentially lowering utility costs. By prioritizing these factors, hospitals can ensure their plumbing systems are safe, efficient, and compliant, ultimately benefiting both patient care and financial health.