Summary: In today’s drive toward sustainability, one critical yet often overlooked factor is the role of reliable piping schematics. Hospitals and large manufacturing plants rely on complex piping systems for essential functions, from water distribution to steam, gases, and chemicals. Keeping these schematics up to date and reliable is not only crucial for operational efficiency but also plays a significant role in achieving sustainability goals. Accurate piping layouts help reduce energy consumption, conserve water, minimize material waste, and ensure compliance with environmental standards.

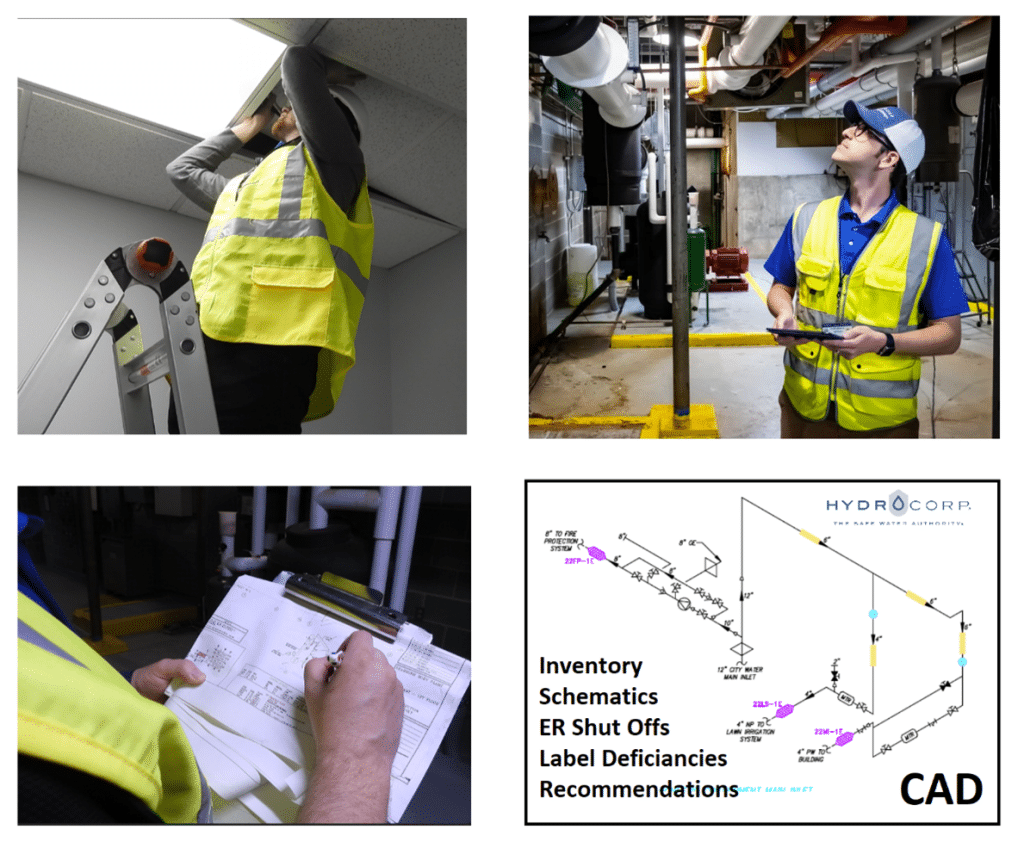

The Practical Guide to Piping Schematics

Reduce time and energy in large-scale expansions and maintenance planning

When rapid response is required to activate critical valves for zone or partial isolation of a system, the difference between sustainable cost impacts and disastrous delays in system control can make or break a facility maintenance budget. With reliable schematics, facilities can:

• Provide accurate and reliable schematics that contractors can plan and estimate from.

• Reduce subcontractor costs with minimized guesswork via reliable piping schematics

• Leverage insurance cost reductions by demonstrating accurate system documentation and safety validations.

Efficient Navigation to Critical Valves/Connections

When rapid response is required to activate critical valves for zone or partial isolation of a system, the difference between sustainable cost impacts and disastrous delays in system control can make or break a facility maintenance budget. With reliable schematics, facilities can:

• Avoid costly damage and excessive system downtime by knowing where all control valves are, and what they serve.

• Maximize the ROI with trusted multi-department use of piping schematics.

Reducing Downtime from faulty connections

Sustainability also encompasses maximizing the lifespan of critical equipment in hospitals and manufacturing plants. Reliable piping schematics ensure that equipment such as pumps, heat exchangers, and compressors are connected properly, and with the appropriate safety valves such as backflow preventers. With accurate schematics, facilities can:

• Extend equipment life by ensuring machinery operates efficiently without strain caused by poor system design.

• Minimize downtime, as reliable schematics enable quicker, more accurate repairs, preventing resource-heavy shutdowns and restarts.

• Improve preventive maintenance, ensuring components like valves are serviced on schedule to prevent breakdowns.

By extending the lifespan of equipment, facilities reduce the need for replacements, supporting sustainability through the conservation of resources.

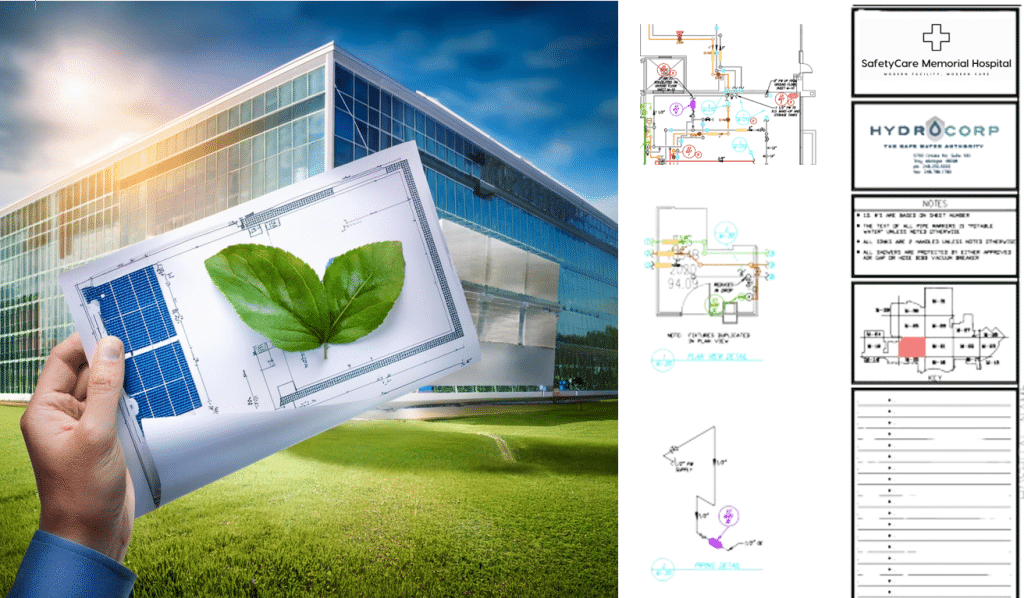

Supporting Environmental Compliance

Sustainability through reliable piping schematics also involves compliance with environmental regulations. Hospitals and manufacturing plants are subject to strict regulations on energy use, water conservation, and waste management. Accurate schematics enable:

• Adherence to water conservation practices, by ensuring systems are designed and maintained to minimize water waste.

• Compliance with energy-efficiency standards, as reliable schematics support optimal system design and operational efficiency.

• Achievement of green building certifications, such as LEED, which rely on efficient piping and energy systems.

Failing to maintain accurate piping schematics can result in operational inefficiencies that lead to non-compliance with these standards, jeopardizing sustainability efforts.

Optimizing Energy Use

Reliable piping schematics are essential for optimizing the flow of resources such as water, steam, and air in hospitals and manufacturing plants. When the exact layout of pipes, valves, and pumps is known, energy-efficient routing becomes possible. Facilities can:

• Identify unsafe and inefficient plumbing bypasses. Reduce energy waste by ensuring pumps and compressors work efficiently, without unnecessary pressure drops.

• Avoid energy loss by detecting and repairing leaks faster, especially in systems like steam that are prone to losing heat energy through undetected leaks.

By maintaining reliable piping schematics, facilities can optimize their energy consumption and reduce their overall carbon footprint, aligning with global sustainability goals.

Conserving Water

Water is a precious resource, especially in hospitals where it is vital for sanitation, sterilization, and cooling, or in manufacturing plants that rely on water for production processes. Reliable piping schematics allow for better monitoring and control of water systems, helping facilities to:

• Detect leaks early, preventing unnecessary water loss.

• Implement greywater reuse systems effectively, ensuring water is recycled and repurposed where possible.

• Maintain cross-connection control, preventing contamination and avoiding wasteful remediation efforts.

Sustainability through reliable piping schematics means more efficient water use and a smaller environmental impact.

Reducing Waste and Material Consumption

When facility engineers work from outdated or inaccurate piping schematics, repairs and maintenance are often imprecise, leading to the overuse of materials and labor. Reliable piping schematics allow for targeted, efficient repairs and replacements. This prevents:

• Unnecessary material waste, as only the necessary sections of pipe or equipment are replaced.

• Over-engineered solutions, which can lead to the waste of resources and longer maintenance timelines.

• Hazardous material mishandling, as better schematics provide clear information about what materials are used and where, improving disposal and recycling efforts.

Minimizing waste directly supports sustainability by conserving materials and reducing environmental impact.

Conclusion: A Sustainable Future through Reliable Piping Schematics

Sustainability through reliable piping schematics is about more than just operational efficiency—it’s about conserving resources, reducing waste, and ensuring long-term environmental stewardship. In hospitals and large manufacturing plants, where the stakes are high, accurate and up-to-date schematics reduce energy consumption, conserve water, and ensure equipment longevity. By prioritizing the maintenance of reliable piping schematics, facilities can meet their sustainability goals while improving overall operational effectiveness.