Snapshot- In the complex ecosystem of a hospital, where every system must work seamlessly, the plumbing infrastructure is often overlooked. Yet, it is vital to maintaining operational continuity, ensuring patient safety, and complying with regulatory requirements. Every valve and bypass in a hospital’s piping system is a critical component, and understanding their locations and functions is essential. Here’s why precision matters and how investing in accurate piping schematics can transform your facility’s maintenance strategy.

Top 10 Piping Issues Facing Healthcare Facilities & How to Solve Them

1st: Ensuring Patient Safety

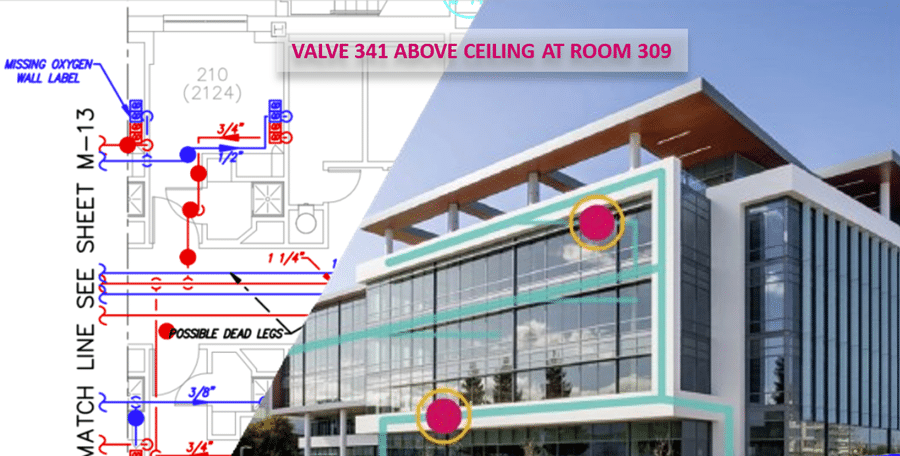

Hospitals rely on safe and uninterrupted potable water supplies for patient consumption, care, sterilization, and sanitation. A single misstep—like an inaccessible or mislabeled valve—can compromise water quality or availability. Accurate schematics ensure maintenance teams can quickly locate and operate valves during emergencies, minimizing disruptions that could put patient safety at risk.

Scenario: During a routine water quality test, a maintenance team detects elevated bacteria levels in a potable water line feeding the ICU. Without accurate schematics, identifying and isolating the affected section takes hours, delaying the implementation of alternative water solutions. However, with precise schematics, the team quickly locates a bypass valve, isolates the contaminated section, and redirects clean water to the ICU within minutes. The rapid response prevents potential infections and reassures staff and patients.

2nd: Supporting Emergency Response

Water-related emergencies, such as pipe bursts or cross-connection contamination, require immediate action. Without precise piping schematics, locating the right valve or bypass can take precious minutes, or worse, hours. A detailed schematic acts as a roadmap, enabling swift action to isolate issues, redirect water flow, and restore operations.

Scenario: A sprinkler system pipe bursts in a surgical suite during the middle of an operation. Water begins pooling on the floor, endangering sterile conditions. Thanks to precise piping schematics, the maintenance staff knows exactly where to shut off the water without disabling the entire hospital’s fire suppression system. Within minutes, the leak is contained, and surgery can proceed with minimal delay, avoiding costly room downtime and maintaining patient care continuity.

3rd: Reducing Maintenance Costs

Inaccurate or outdated schematics lead to inefficiencies and higher costs. Maintenance teams may spend unnecessary time locating valves, diagnosing problems, or accessing hard-to-reach components. Precision reduces labor hours and the risk of errors, directly impacting your bottom line.

Scenario: A routine inspection reveals a slow leak in a valve located within a high-traffic corridor. Without detailed schematics, the maintenance team spends hours trying to locate the shutoff valve, requiring multiple rounds of exploratory labor. With accurate schematics, they quickly identify the problematic valve and isolate it within 30 minutes, saving hours in labor costs and minimizing disruption to hospital operations.

4th: Streamlining Renovations and Upgrades

Facility renovations often require water shutoffs or system adjustments. Without accurate schematics, contractors may inadvertently disrupt other parts of the system, causing delays and additional expenses. Updated piping diagrams simplify planning, reducing project risks and ensuring timelines are met.

Scenario: A hospital plans to install a new sterilization unit, which requires modifications to existing water supply lines. Without updated schematics, contractors mistakenly shut off water to the NICU, delaying the installation and causing logistical headaches. Precise schematics would have shown them an alternative shutoff point, ensuring the NICU’s water supply remained uninterrupted while the upgrades were completed.

5th: Proactive Maintenance Planning

Piping systems in hospitals are complex and often run continuously. Precision in schematics allows maintenance teams to proactively monitor critical components like valves and bypasses. This prevents small issues from escalating into major disruptions, extending the lifecycle of your plumbing infrastructure.

Scenario: A hospital’s facility team schedules a routine inspection of critical valves in a pediatric ward. Thanks to precise schematics, they quickly identify and replace an aging valve that was showing early signs of corrosion. By addressing the issue proactively, they prevent a potential failure that could have required an emergency water shutdown, significantly disrupting operations and risking patient care.

6th: Building a Culture of Precision

Hospitals cannot afford to compromise on precision when it comes to their piping systems. Each of the scenarios above highlights the critical role that detailed and up-to-date piping schematics play in ensuring safety, efficiency, and compliance.

Steps to Build Precision into Your Piping Schematic and Documentation System:

- Periodic Surveys: Schedule regular visual inspections to validate schematics against on-the-ground conditions.

- Digital Transformation: Transition from static paper documents to dynamic, digital schematics that are accessible and easy to update.

- Staff Training: Ensure all maintenance staff can interpret schematics and apply them effectively during emergencies or routine tasks.

Conclusion: Precision Saves Money and Lives

Every valve and bypass matters because every moment counts in a hospital. With accurate piping schematics, hospitals can reduce response times, avoid costly errors, and ensure uninterrupted care patients rely on.

Don’t wait for a crisis to uncover the gaps in your system. Take the proactive step of investing in detailed and accurate schematics to empower your facility team and protect your hospital’s operations.

Precision isn’t optional—it’s essential for excellence.