Key Message:

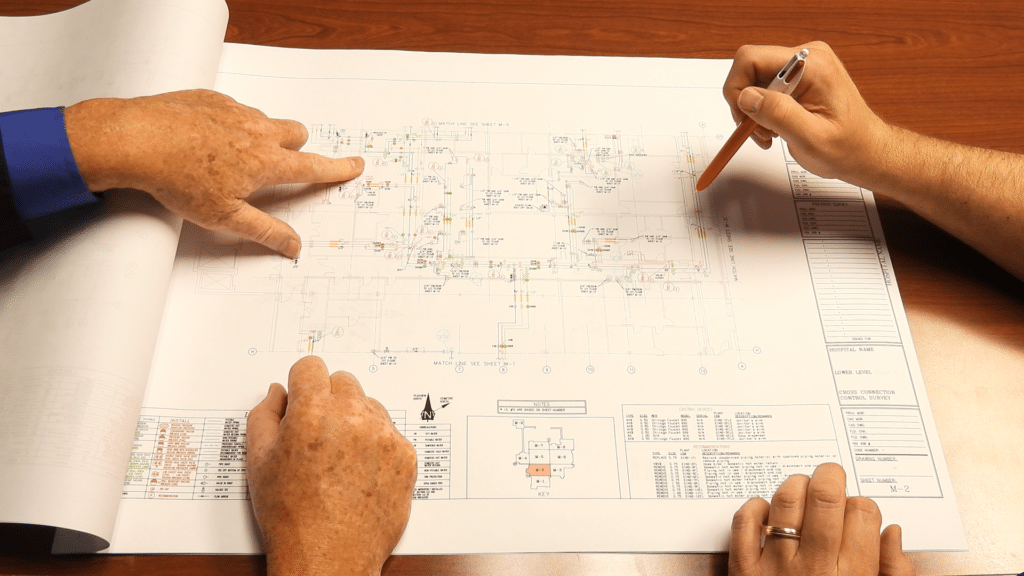

Imagine visually tracing a 500-foot section of potable water piping and all of the associated connections in a hospital or food processing facility. The observation of that portion of the drinking water system could reveal up to 50 or more important valves that serve as critical control points and safety of the water quality. From backflow preventers to emergency shut off valves, having reliable piping schematics that indicate their precise location and purpose is essential for daily facility operations.

The Practical Guide to Piping Schematics

What exactly are we citing:

- Valves: Regulate water flow and isolate system sections during maintenance.

- Points of Use (POUs): Locations where water is accessed, such as faucets or equipment connections.

- End-Point Use Valves: Typically integrated into POUs, these valves control flow directly at the point of use, allowing for localized shutdown without affecting the entire system.

- Backflow Preventer Assemblies: Dedicated check valves that prevent backflow of potable water supply and require periodic testing by certified technicians. Typically installed to zone-isolate and end point of use connections.

- Pressure Reducing Valves: Adjustable valves to regulate line pressure to a particular zone of piping or point of use.

- Valve Tags: Physical tags attached at the valve that indicate valve purpose and system served.

Data and shared knowledge indicate:

- Mainline Valves per 500 Feet:

- Based on industry data, including research from Virginia Tech and the American Water Works Association (AWWA), there are typically 4 to 6 mainline valves per 500 feet of potable water piping in commercial and institutional settings. These valves are crucial for isolating sections of the system during repairs.

- Points of Use (POUs) per 500 Feet:

- POUs can range from 10 to 25 valved connections per 500 feet, depending on the facility’s requirements. Hospitals often require more frequent POUs to meet health and safety regulations, while manufacturing facilities might need fewer based on operational needs.

- End-Point Use Valves:

- Every POU typically has an end-point use valve integrated within it. Thus, the number of these valves corresponds directly to the number of POUs, meaning there are generally an additional 10 to 25 valved connections per 500 feet of piping. These valves are vital for enabling localized maintenance and ensuring the system remains operational during minor repairs.

Factors Influencing Distribution:

- Facility Type and Function: Hospitals require higher densities due to frequent access needs, while manufacturing facilities may have lower densities depending on their specific operations.

- System Redundancy: Valving strategies like the N and (N-1) rules help minimize the impact of valve failures, ensuring system reliability.

- Regulatory Standards: Health and safety regulations often dictate the minimum number of valves and POUs, particularly in sensitive environments like hospitals.

Importance of Accurate periodic updates to keep schematics accurate:

Accurate onsite surveying is essential for maintaining system integrity, planning upgrades, and ensuring compliance with safety standards. Surveyors should document all valves and POUs, assess their condition, and determine if additional components are needed to enhance system performance.

What does this tell us:

Having reliable schematics and records that reflect actual valve locations, conditions and purposes is critical for effective and facility operations. On average, facilities should expect 4 to 6 mainline valves, 10 to 25 POUs, and a corresponding number of end-point use valves per 500 feet of piping. These figures should be adapted to meet the specific needs of each facility, ensuring optimal system performance and safety.

References:

- American Water Works Association (AWWA). (2022). Standard Practices for Valve and Hydrant Management.

- Jun, Hwandon. (2005). Strategic Valve Locations in a Water Distribution System. Virginia Tech. Available at VTechWorks.