Summary

For hospitals, industrial, and manufacturing facilities, the accuracy of piping schematics is essential for safe, efficient, and regulatory-compliant operations. However, over time, these documents often become unreliable, introducing risks and inefficiencies. This post explores the primary reasons why piping schematics lose reliability, examining issues ranging from deferred updates to the challenges of complex retrofits. Understanding these factors allows facilities to mitigate risks by implementing maintenance practices that keep their documentation relevant and dependable.

The Practical Guide to Piping Schematics

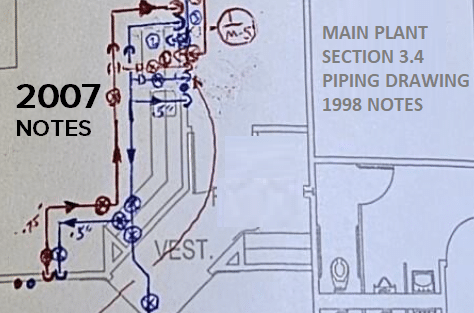

1. Lack of Regular Updates

Overview: Regular changes in facility piping—whether planned upgrades or small, incremental repairs—often go undocumented. Over time, these undocumented changes accumulate, creating significant discrepancies between the physical system and its schematics.

Impacts:

- Staff may lack current information, increasing response times for maintenance and emergency repairs.

- System vulnerabilities, such as outdated valve locations or missing cross-connection points, may go unnoticed.

Solution: Implement a structured process for regularly scheduled reviews and updates of piping diagrams, ideally as part of any significant facility maintenance or inspection effort.

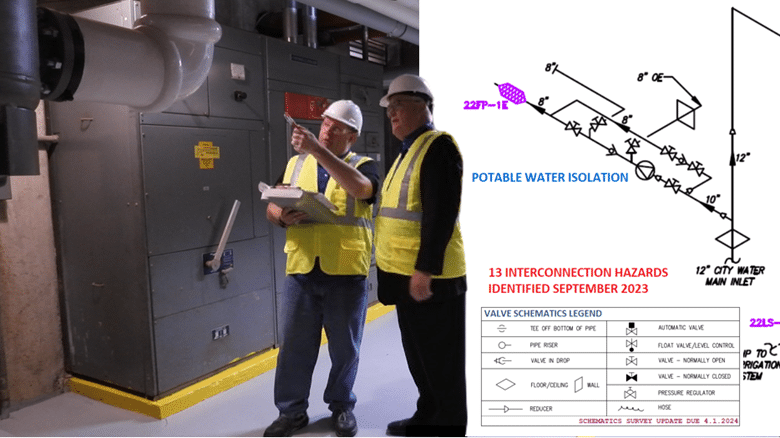

2. Complexity of Retrofitted Systems

Overview: Facilities, particularly older ones, often undergo retrofits to accommodate new technologies or regulations. These changes can introduce additional piping that’s interconnected with the original infrastructure, complicating the system’s design and often bypassing updates to the original schematics.

Impacts:

- Inaccuracies in retrofitted systems can lead to misinterpretation of flow paths and system interdependencies.

- Over time, these inconsistencies can undermine confidence in the schematics, making staff hesitant to rely on them.

Solution: Integrate retrofits directly into a schematic maintenance plan, ideally with clear version control, and invest in professional documentation of complex retrofits.

3. Human Error During Modifications

Overview: When on-site staff or contractors make updates, even minor human errors in documenting changes can cause significant schematic inaccuracies over time. This is especially common during emergency repairs when priority is placed on functionality rather than recordkeeping.

Impacts:

- Incomplete or incorrect documentation may leave future staff unaware of changes, complicating system maintenance.

- Mistakes in emergency procedures could arise from unexpected configurations, impacting safety and compliance.

Solution: Encourage clear documentation protocols for all maintenance staff, stressing the criticality of accurate schematic updates even during urgent situations. Regular audits of the schematics can catch and correct these issues early.

4. Evolving Regulatory Standards

Overview: Changing health, safety, and environmental regulations may necessitate modifications in a piping system’s design or configuration. For instance, new cross-connection control standards may require backflow preventers to be installed, altering the piping layout. Often, updates to schematics lag behind regulatory changes.

Impacts:

- Compliance risks arise if regulatory inspections reveal non-conformity between schematics and installed equipment.

- Lack of updated schematics can complicate proof of compliance, potentially affecting funding, permitting, or operational approvals.

Solution: Engage compliance teams during regulatory updates, ensuring all new installations or adjustments are included in the schematics. This proactive approach can reduce compliance costs and ensure documentation supports inspections.

5. Aging Systems and Unknown Legacy Modifications

Overview: Many older facilities were built with legacy systems that have been modified over the years, often without thorough documentation. These systems may also contain obsolete components no longer in use, which can further obscure the reliability of schematics.

Impacts:

- Without historical insight, maintenance staff may encounter unexpected issues, from incorrect valve locations to unmarked bypasses.

- Unreliable schematics reduce efficiency, increasing downtime and repair costs as technicians try to navigate undocumented sections.

Solution: Consider a full system survey by professional engineering teams for older systems. These teams can create a modern baseline schematic, clarifying the current state of the piping network and removing any outdated or inaccurate details.

6. Digital and Physical Schematic Degradation

Overview: Both digital and hard-copy schematics can degrade over time. Digital files may become incompatible with newer software or lost if not backed up properly, while physical documents are prone to wear and environmental damage.

Impacts:

- Degraded schematics reduce staff accessibility, especially in emergencies.

- Lost or unreadable documents can stall repairs, requiring costly and time-intensive surveys to regain the information.

Solution: Invest in digital backups and implement consistent document management practices. For physical copies, ensure they’re stored securely, with regular checks for legibility and damage.

Conclusion

Piping schematics are essential assets for the safe and effective operation of any facility with complex water distribution systems. As systems age and adapt to evolving demands, the reliability of these documents often declines due to a variety of factors. By understanding these challenges and taking proactive steps to regularly update and maintain schematics, facilities can prevent costly repairs, reduce compliance risks, and ensure that staff can confidently rely on their documentation.

Maintaining reliable piping schematics should be a priority for any facility seeking operational efficiency, safety, and regulatory compliance. HydroCorp specializes in comprehensive schematic creation and management solutions, including accurate onsite surveying, digital documentation, and schematic maintenance services. By partnering with a dedicated service provider, facilities can sustain the integrity of their piping schematics, mitigating the risks of outdated documentation.