Summary:

In the world of water safety and plumbing systems, two distinct roles are critical for ensuring the integrity of a potable water supply: the cross-connection control surveyor and the backflow preventer tester. While both are essential for safeguarding against contamination and maintaining regulatory compliance, they serve different functions within the broader scope of cross-connection control and backflow prevention.

Understanding the differences between these roles can help building owners, facility managers, and public water system operators make informed decisions about how to maintain their potable water systems in a safe and compliant manner.

Cross-Connection Control vs. Backflow Prevention: What’s the Difference?

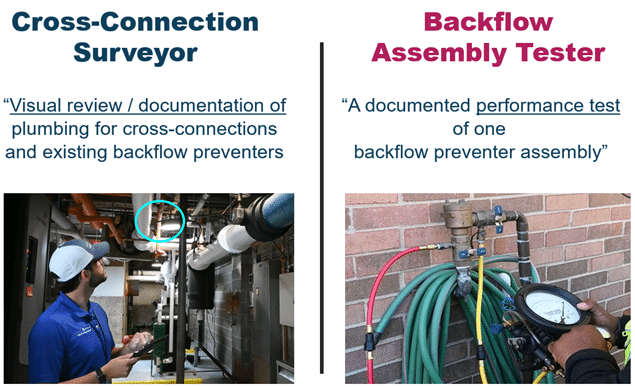

The Role of a Cross-Connection Control Surveyor

A cross-connection control surveyor focuses on identifying and assessing potential or actual cross-connections within a building’s or facility’s plumbing system. Their primary role is to conduct comprehensive surveys to detect where potable water systems may be at risk of contamination due to improper plumbing connections with non-potable sources.

Qualifications and Certifications Required:

Some but not all states have specific certification or qualification requirements for individuals performing cross-connection control surveys. Consult your state and local requirements for cross-connection control surveys.

Responsibilities of a Cross-Connection Control Surveyor:

- Performing Risk Assessments: Surveyors are trained to inspect the entire plumbing system and evaluate any potential points of contamination. This includes identifying improper installations, cross-connections that haven’t been addressed, or areas where backflow could occur if preventive measures aren’t in place.

- Documenting Findings: After completing the survey, the surveyor provides a detailed report outlining the locations of identified cross-connections, the level of risk, and recommendations for corrective actions. This documentation is essential for building owners and water system operators to implement necessary safeguards.

- Recommending Solutions: Based on their findings, surveyors offer recommendations for installing or upgrading backflow prevention devices, isolating hazardous areas, or modifying plumbing layouts to eliminate risks.

- Regulatory Compliance: Surveyors ensure that all cross-connection control measures comply with local, state, and federal regulations. They help building owners understand their obligations under water safety laws, including the Safe Drinking Water Act, and advise on the best practices for maintaining a safe water supply.

In essence, the cross-connection control surveyor is a detective, identifying potential hazards in the water system and working to prevent contamination before it occurs.

The Role of a Backflow Preventer Tester

A backflow preventer tester, on the other hand, is responsible for testing, inspecting, and maintaining backflow prevention devices that are already installed in the plumbing system. Backflow preventers are mechanical devices—such as reduced pressure zone (RPZ) assemblies, double check valves, and vacuum breakers—that are designed to prevent contaminants from flowing back into the potable water system.

Responsibilities of a Backflow Preventer Tester:

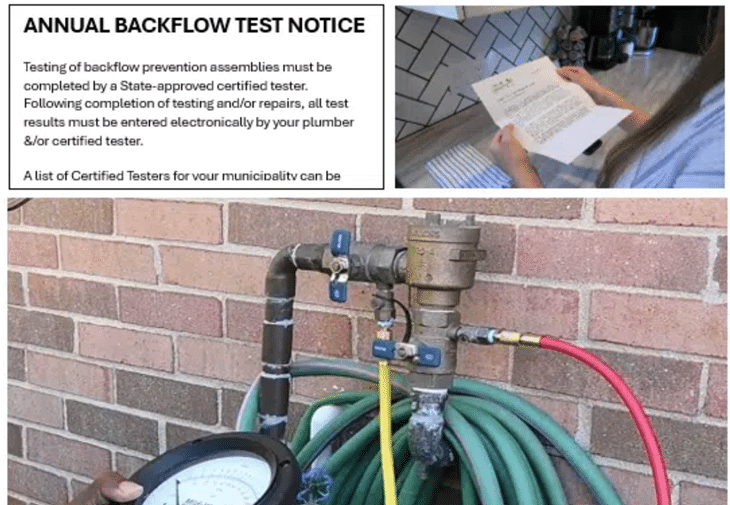

- Performing Functional Testing: Testers conduct annual (or more frequent) tests on backflow prevention devices to ensure they are functioning correctly. This involves simulating potential backflow conditions and confirming that the devices operate as intended to block contamination.

- Inspecting for Damage or Wear: Over time, backflow preventers can degrade, malfunction, or become damaged due to wear and tear, environmental conditions, or improper installation. Testers visually inspect the devices for signs of leakage, corrosion, or physical damage that could compromise their performance.

- Repairs and Maintenance: When a backflow prevention device fails a test, the tester is responsible for repairing or replacing it. This may involve cleaning internal parts, replacing faulty components, or reinstalling the device according to manufacturer specifications and local codes.

- Certification and Compliance: After completing the test, backflow preventer testers issue a certification report documenting the results. This documentation is often required by local authorities to demonstrate compliance with backflow prevention regulations. Testers ensure that building owners maintain up-to-date records of their testing and certification.

The backflow preventer tester’s role is reactive in nature—they ensure that the devices meant to protect the water system are functioning as they should.

Key Differences Between the Two Roles

While both the cross-connection control surveyor and the backflow preventer tester are crucial to water safety, their focus and responsibilities differ significantly:

| Cross-Connection Control Surveyor | Backflow Preventer Tester |

| Focuses on Identifying Risks: Surveys the entire plumbing system to identify potential or existing cross-connections that could cause contamination. | Focuses on Testing Devices: Tests and certifies backflow prevention devices to ensure they are functioning properly. |

| Prevents Contamination: Works proactively to prevent contamination by recommending cross-connection control solutions before issues arise. | Maintains Protection: Ensures that existing protective devices (backflow preventers) are working as intended to stop contamination. |

| Broad Assessment: Inspects all aspects of the water system for risks, including plumbing layouts, equipment connections, and hazardous zones. | Device-Specific: Inspects only the backflow prevention devices that are already installed in specific locations within the plumbing system. |

| Provides Recommendations: Suggests corrective actions, such as installing backflow prevention devices or modifying the plumbing system. | Performs Repairs: Repairs or replaces faulty backflow prevention devices if they are not operating correctly during testing. |

| Survey Frequency: Surveys are typically conducted periodically (every few years or after major system changes). | Testing Frequency: Backflow preventer devices are tested annually (or as required by local codes). |

Why Both Roles Matter

Both cross-connection control surveyors and backflow preventer testers are integral to ensuring the safety of potable water systems. Surveyors help prevent problems by identifying risks and advising on preventive measures, while testers ensure that the backflow prevention devices—once installed—continue to provide reliable protection.

For building owners and facility managers, engaging both professionals is essential to comprehensive cross-connection control. Surveyors assess the overall health and safety of the plumbing system, while testers maintain the integrity of the devices that serve as the final line of defense against backflow contamination.

Conclusion

The roles of cross-connection control surveyors and backflow preventer testers may overlap in the shared goal of protecting potable water systems, but their responsibilities and approaches are distinct. By understanding the differences, building owners can ensure they are employing the right expertise at the right time—whether it’s surveying the system for hidden risks or maintaining the devices that keep contaminants out. Both roles are necessary for a well-rounded cross-connection control program, ensuring the safety and reliability of potable water for all building occupants.