Things To Consider:

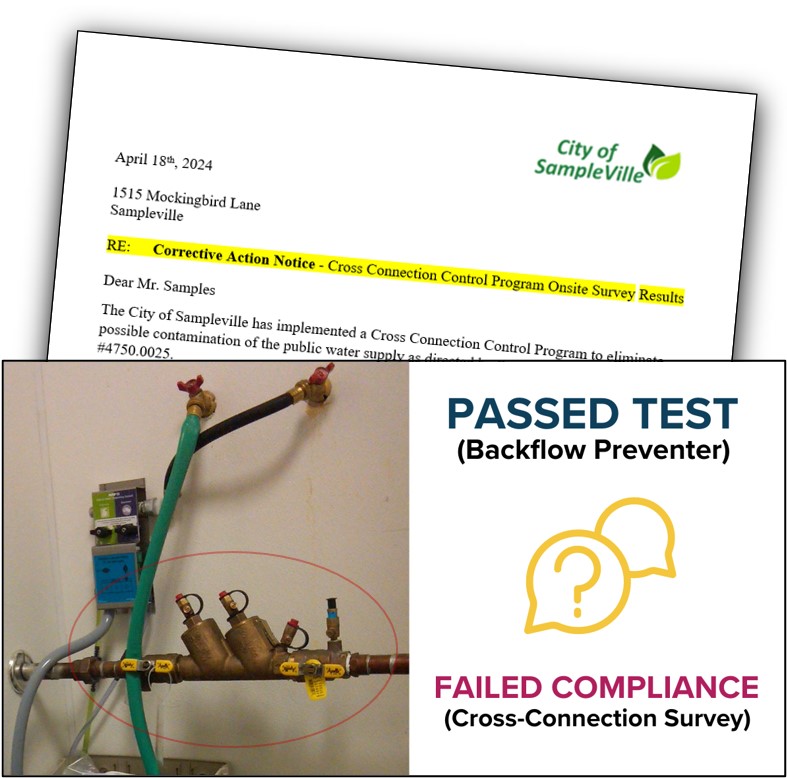

- Testing of the backflow preventers connected to your public water distribution system, while critically important, is only part of an overall cross-connection control program.

- Surveys and assessments are the only way to verify the protection or elimination of undetected cross-connections in any given facility or building. Find out what hazards may be lurking out in the distribution system HERE.

- Follow up inspections to verify corrective action requirements have been fulfilled is a necessity.

When considering the most effective way to safeguard your public water system from backflow contamination, the distinction between data collected from routine backflow preventer assembly testing and comprehensive cross-connection control program activities can be a source of confusion for many. While both entail the collection of data, their purposes, methodologies, and implications are fundamentally distinct. Let’s dig deeper and unravel the differences between these two types of data collection and underscore their unique roles in ensuring the mitigation of backflow hazards in public water systems.

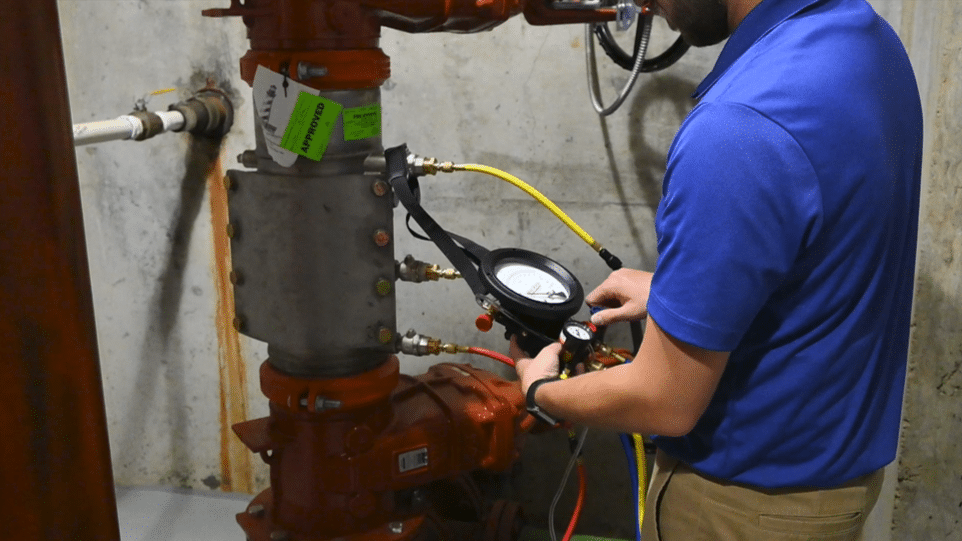

Backflow Preventer Assembly Testing

Backflow preventer assembly tests, often mandated by state regulations and codes, serve as a critical component of maintaining the safety of service connections in the public water distribution system. These tests, typically conducted by certified technicians, involve testing the functionality of these devices to prevent the reverse flow of contaminated water into the public water supply. The data generated from these tests revolves around the performance of individual backflow preventer assemblies and information on the tested assembly including its make, model, and size, along with the test date and the identity of the tester.

However, it’s essential to recognize that while this data provides invaluable insights into the operational status of specific, testable backflow prevention assemblies, it offers only a partial glimpse into the broader landscape of cross-connection control efforts within a water system. This is where the distinction lies: while backflow preventer test data focuses on the functionality of individual devices, cross-connection control program activities encompass a more holistic approach to assessing, identifying, and mitigating potential hazards throughout the entire water distribution network.

Comprehensive Cross-Connection Control Programs

Cross-connection control program activities encompass a wide range of activities, including onsite surveys and compliance audits. Unlike the narrow scope of backflow preventer assembly tests, which can only verify if a known backflow preventer is still installed and properly functioning, these activities cast a much wider net. The aim of a comprehensive Cross-Connection Control Program is to identify and eliminate unprotected cross-connections throughout the water distribution system, including residential, commercial, and industrial premises.

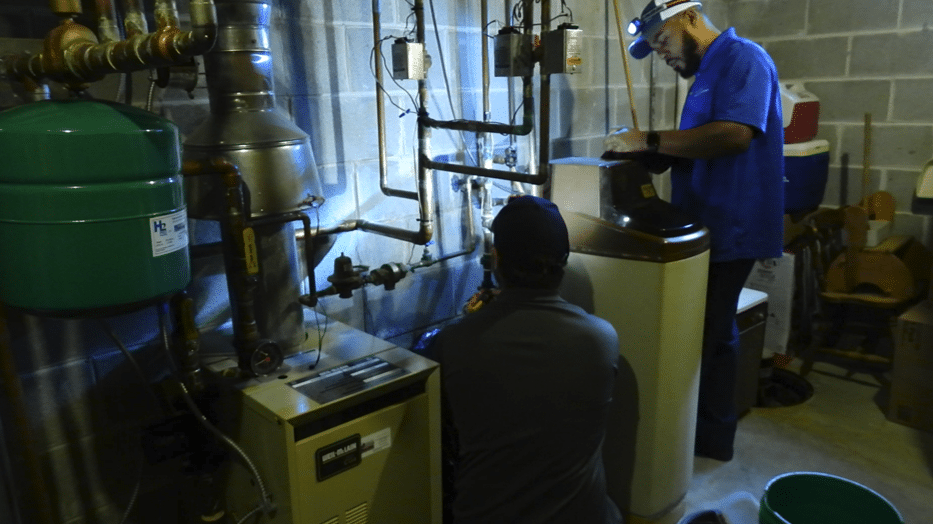

Cross-Connection Surveys/Assessments

Onsite surveys, for instance, involve meticulous inspections conducted by trained professionals to identify and eliminate any actual or potential cross-connections between potable water sources and potential hazards. These surveys go far beyond merely testing backflow preventers, as a “point of use” survey involves the surveyor physically coming onsite and following the water lines from the point of service connection to each end point use. The data gleaned from such surveys provides invaluable insights into the prevalence and nature of cross-connection hazards within a community, guiding targeted interventions. Data collected could include number of unprotected cross-connections, information on newly installed backflow prevention assemblies, and even the identification of broken backflow prevention assemblies in need of repair. The outcome will be a detailed record of every utility sink, hose spigot, irrigation system, and process water connection that exists within a given property. It will also include corrective action requirements for any non-compliant connections.

True Compliance

Compliance inspections, another integral facet of cross-connection control programs, entail following up on each and every one of the required corrective actions that the initial surveyor made. It is critical to remember that is not enough to identify unprotected cross-connections; they must be eliminated. These compliance inspections verify that a non-compliant connection has been properly removed or protected. In the case of a water customer installing a new backflow prevention assembly to protect the uncovered cross-connection, the compliance surveyor will make note of the new assembly and the water utility will add the new assembly to their record of testable assemblies in the distribution system that require periodic testing.

Wrap Up

In essence, while backflow preventer assembly test data offers critical insights into the operational status of individual assemblies, it represents just one piece of the larger puzzle in cross-connection control. Comprehensive cross-connection control program activities, encompassing onsite surveys and compliance inspections, offer a more holistic approach to assessing, identifying, and mitigating potential hazards within public water systems. Without these activities to locate and eliminate cross-connections, many hazardous connections will go undetected; and undetected is unsafe. By understanding and leveraging the distinct roles that each component of a comprehensive plan plays and the importance of each set of data, water utilities can enhance their capacity to safeguard public health and ensure the integrity of their potable water supply.