Snapshot

Industrial facilities face increasing pressure to comply with stringent safety standards and ensure safe drinking water for employees and production purposes. One of the most impactful strategies? Maintaining accurate and up-to-date piping schematics for potable water plumbing systems. Beyond operational efficiency and safety, this investment can lead to reduced insurance premiums. But do these savings offset the costs of updating your piping schematics?

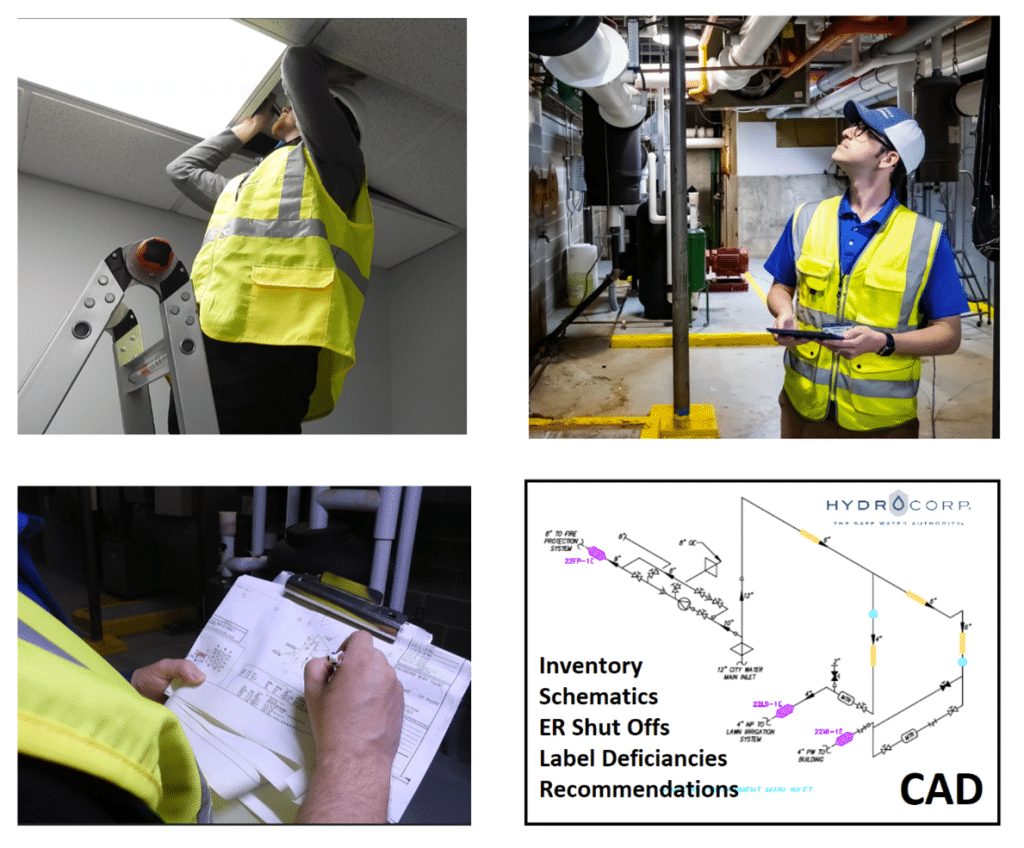

4 Proven Tips to Secure Reliable Piping Schematics in Your Facility’s Budget

The Insurance Perspective: Why Accuracy Matters

Insurance companies like Travelers and Zurich Insurance emphasize accurate piping schematics as an integral part of comprehensive risk management strategies. These companies often assess a facility’s water safety protocols when determining premiums. Facilities that proactively address the risk of water contamination—such as those stemming from cross-connections—are frequently rewarded with lower insurance rates.

Travelers, for example, provides detailed risk control resources to clients that highlight how accurate documentation of potable water systems can prevent contamination incidents. Their consultations primarily focus on identifying and mitigating exposures that result in costly claims, underscoring how precise schematics help industrial facilities stay ahead of potential risks such as unprotected cross-connections, insufficient backflow prevention, mislabeled piping, and piping conditions that proliferate legionella.

Similarly, Zurich Insurance highlights the role of strict water safety controls—including precise piping schematics—in reducing water contamination claims. Many insurers recognize that facilities with robust cross-connection safeguards and accurate system documentation are better prepared to manage emergencies, which translates into reduced liability and lower cost to insure.

Cost & Time Savings

The cost of updating piping schematics often depends on a facility’s size, complexity, and the state of its existing documentation. While the upfront investment can be significant, the long-term benefits justify the expense. Accurate schematics:

- Reduce Claims: Fewer contamination incidents mean fewer insurance claims, saving the facility money on direct costs and premium increases.

- Qualify for Premium Discounts: Facilities that demonstrate strong risk management practices are often eligible for premium reductions, as supported by insurance industry guidelines.

- Enhance Operational Reliability: In addition to insurance benefits, updated schematics improve emergency response times and reduce downtime during maintenance or repairs.

Additional Endorsements

State agencies and industry organizations echo the perspective of these insurance providers. For instance, the Virginia Department of Health promotes maintaining accurate water system documentation as a best practice for contamination prevention. Similarly, resources like DC Water’s cross-connection program guidelines underscore the operational and safety benefits of precise schematics.

The Bottom Line

By collaborating with risk management consultants and insurers, facilities can calculate the potential savings from premium reductions. When weighed against the cost of updating piping schematics, many facilities find that the insurance savings alone cover a significant portion of the project expenses over time.

Investing in accurate piping schematics isn’t just a safety measure—it’s a financial strategy. Facilities that take this proactive step position themselves for operational stability, reduced liability, and tangible cost savings. By framing the investment as part of a broader risk management initiative, many organizations can unlock value that extends far beyond compliance.