Legionella-related disease cases in the United States have increased more than five times from 2000 to 2017—and those numbers haven’t shrunk in recent years. As disease rates have increased, so has awareness of Legionella contamination. The onus doesn’t fall just to public water systems—businesses with complex plumbing need to protect their potable water systems and address areas of high risk.

In a recent HydroCorp webinar, “Legionella Risk Mapping: Smart Water Assessments for Safer Facilities,” Gary McLaren and Glenn Adamus discussed the risk of Legionella contamination in industrial and commercial facilities, and how to mitigate it.

By the Standard

Requirements for protection of potable water exist at the federal and state level, and associations have developed guidance and best practices to help facilities maintain safe water in working environments.

ASHRAE 188

ASHRAE 188 is the “gold standard” for facilities, developed to recommend minimum levels of Legionella risk management in internal water systems. The standard defines the types of facilities required to maintain a water management plan and provides a framework to establish that plan.

“There’s a reason that ASHRAE 188 exists in this industry,” says Adamus. “Consider this the standard, refer to it, follow it, and use it as a framework to develop an overall water management plan.” According to Adamus, if you want to define a plan specific to Legionella control, as described in the standard, you must:

- Describe your facility’s water systems

- Develop flow diagrams

- Analyze those systems

- Design control measures and prescribe control limits

- Verify and validate your plan

Verification and validation are processes by which you confirm your water management plan achieves its stated goals. Verification ensures plan activities occur and control measures are in place; validation typically involves environmental sampling for Legionella bacteria.

OSHA

All employers are subject to OSHA regulations, which do cover—at a high level—potable water protection measures. Regulation 1910.141(b)(1)(i) specifies that “potable water shall be provided in all places of employment,” including for activities such as drinking, washing, and cooking.

“In essence, this standard requires employers to provide safe, potable water for employees and visitors,” Adamus explains. “We need to look at drinking quality at large.” Some organizations even maintain two separate policies: one for drinking water and one specifically designed for Legionella control.

While this is an important standard, recognize that it’s not prescriptive in nature—you won’t find direction on establishing a water management program in OSHA. While it sets the imperative to maintain safe drinking water, it doesn’t outline how.

The Practical Guide to Piping Schematics

Documentation & Application

“Documentation is key,” Adamus says. “If you have 50 control measures, the question is: How do you prove to someone that you’re actually performing these control measures?” Not only do you need to document sample test results, but you need to document your system

Process Flow Diagrams

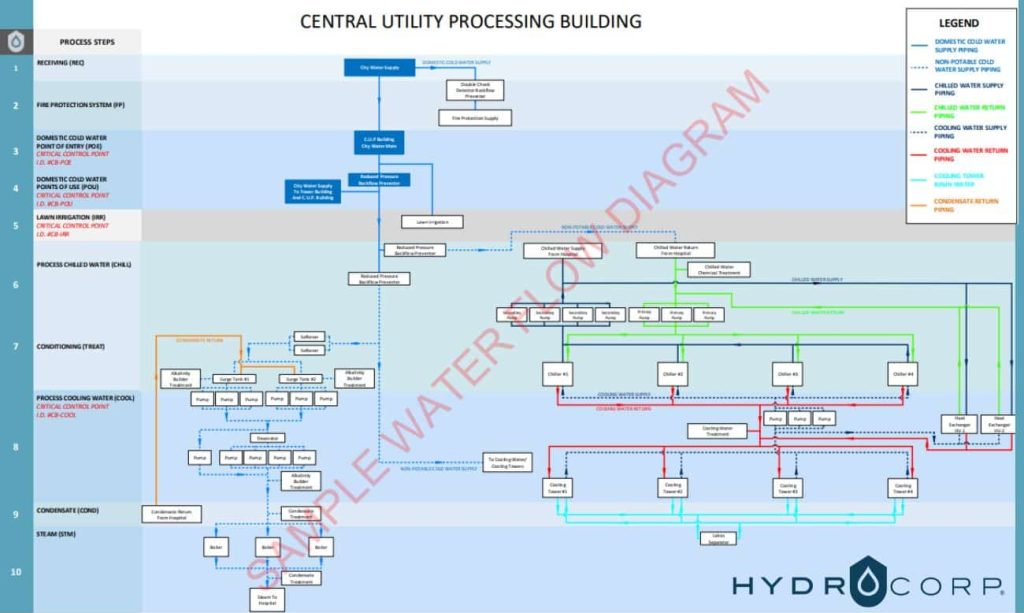

Process flow diagrams are just what they sound like: a relatively simple and straightforward diagram, “cursory in nature,” that documents the flow of water throughout a system, from source to end point usage.

For the purposes of Legionella control, process flow diagrams should be intuitive and accessible to a broad audience, allowing a general understanding of how water is being received and processed throughout a building.

These diagrams play a necessary role in any water management program but, by themselves, can’t protect against and prevent Legionella contamination. Especially after a building has confirmed the presence of Legionella bacteria within the water system, flow diagrams can’t help you find the culprit—whether it’s a cross-connection, a dead leg, or another risk area.

Piping Schematics

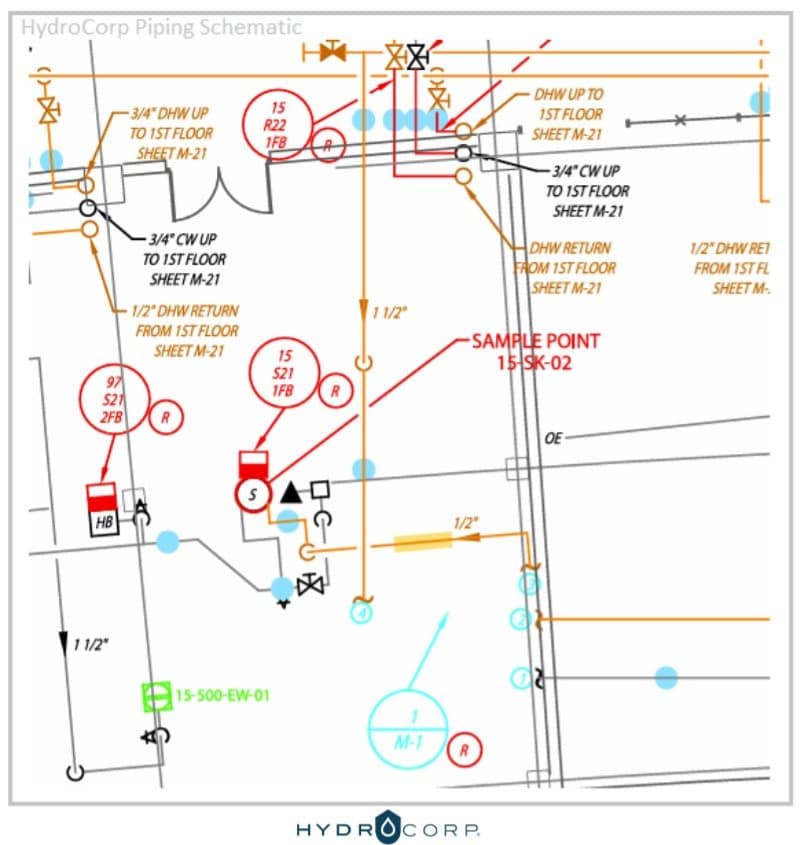

When process flow diagrams can’t inform you of the state of your system and areas of risk, what do you need? “We’re very commonly asked to develop schematics because a facility doesn’t have a complete picture of the water distribution system within their building,” says Adamus. These schematics trace the pipes throughout the entire building and help you identify dead legs and other high-risk sections of piping. Schematics also pinpoint the exact location of shut-off valves and other plumbing components for easier maintenance and improved emergency response—so, if you find Legionella, you can quickly respond.

With schematics, “you’re getting so much information—where all your assets are, where your acute risks are,” Adamus says. The initial investment of time and effort into developing schematics provides a wealth of information that can guide your water management program and Legionella prevention efforts.

When you work with HydroCorp to develop your schematics, you’ll receive a detailed report specifying all recommended corrective actions like labelling, removing dead legs, and correcting unprotected cross-connections.

The Zero Goal

The goal of water management programs in general, and Legionella control efforts specifically, is zero disease. That doesn’t mean you’ll never find any bacteria in your water systems, but that your proactive analysis of your system and regular sampling prevents contamination and resulting disease.

Validation—usually sampling—helps you determine whether your plan meets that goal. While universal criteria for acceptable levels of bacteria doesn’t exist, you should develop (or work with a third party to develop) guidelines for your facility. What levels are unacceptable? What remediation actions will you take if you identify unacceptable levels in your facility?

Monitoring your water management program ensures it’s effective. Staying on top of your potable water piping systems is the most proactive way to prevent Legionella contamination and the resulting disease.

Ready to learn more about how HydroCorp can support your facility’s Legionella control and water management efforts?