Quick Notes:

- In large, heavy industry or manufacturing facilities, employees often distrust facility water due not to the source water or maintenance quality, but because of the inherently complex and interconnected infrastructure of the system and the processes that it is connected to.

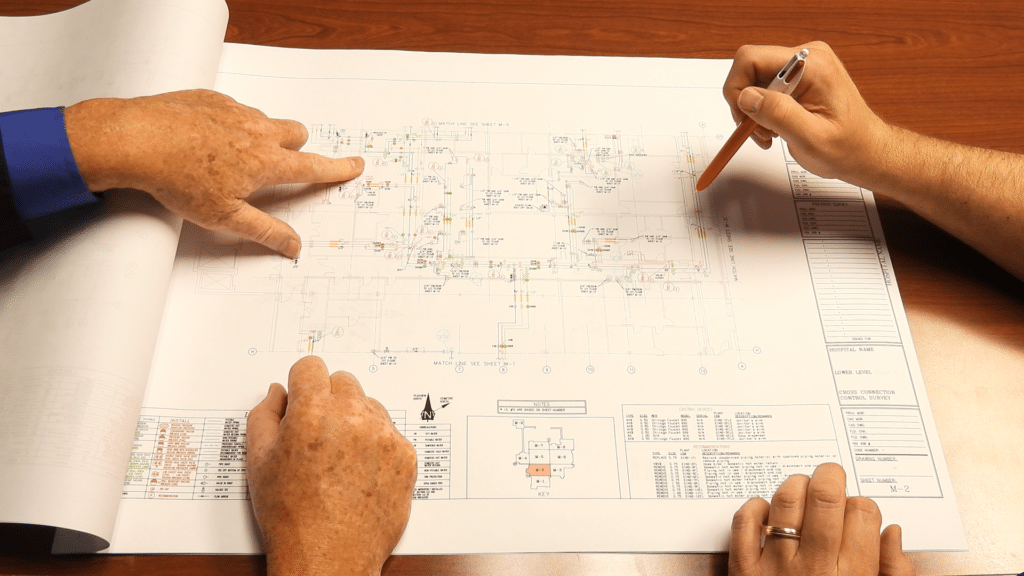

- Conducting onsite visual surveys and keeping updated piping schematics is essential for identifying vulnerabilities and maintaining system integrity for safe drinking water through out a facility.

- Regularly informing employees about water safety measures and involving them in initiatives can build trust and ensure a healthier workplace environment.

4 Proven Tips to Secure Reliable Piping Schematics in Your Facility’s Budget

In the heart of any heavy industry, water is a fundamental necessity, critical for both operations and employee well-being. Yet, in many such facilities, a peculiar phenomenon persists: employees decline to drink from the water fountains. While the provision of bottled water may be a convenient solution, the underlying issues tied to the potable water within the plant remain largely unaddressed. This reluctance isn’t merely a matter of preference, but a deep-seated mistrust rooted not in the facility managers or maintenance teams, but in the complexities and uncertainties of the infrastructure of the water system itself.

The Genesis of Distrust

The phrase “We don’t drink the water here” resonates across many industrial settings, particularly with heavy manufacturing facilities. This sentiment stems from a multifaceted mistrust of the water system of piping and plumbing, not necessarily the water source itself. The city water supply is perfectly safe, and maintenance teams are highly competent. However, the intricate web of infrastructure has evolved over the years with updates, changes, and repairs that have occurred over the years.

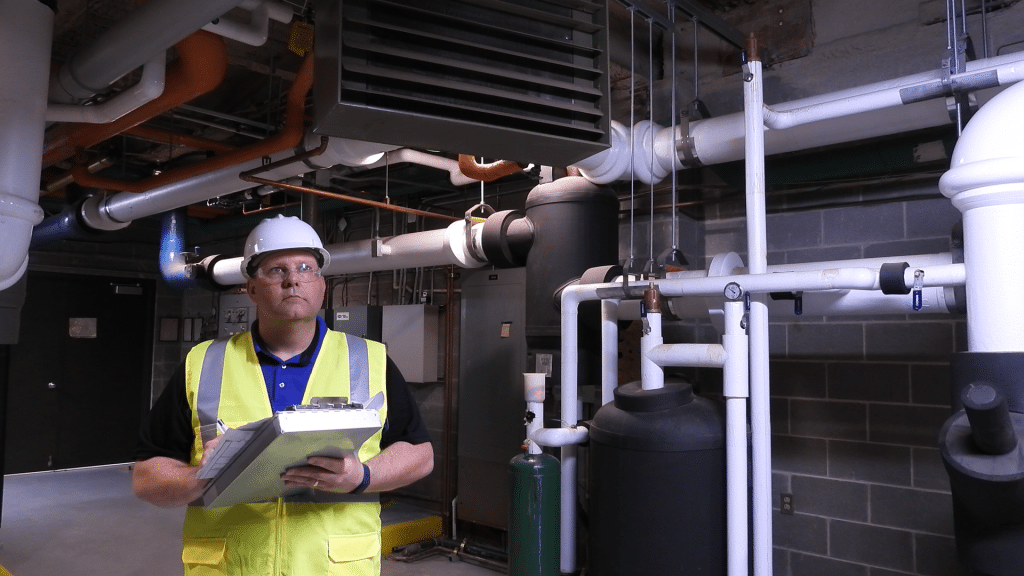

In a sprawling industrial compound, the water system is an interconnected network spanning multiple buildings and operations. Over time, as the facility expands and evolves and as buildings are added or demolished, the intricacy of its water system grows more and more complex. New extensions, repurposed spaces, and additional processes integrate into the existing infrastructure, creating a convoluted and often opaque system. This gradual evolution can result in a labyrinthine of a network where the origins and paths of water lines become unclear, and confidence in their purity diminishes.

The Monstrosity of Complexity

Consider a large manufacturing compound with multiple buildings and diverse functions. Each addition or modification to the water system introduces new variables and potential points of contamination. Pipes from different eras, materials, and maintenance histories intertwine, creating a daunting puzzle for even the most experienced maintenance teams. This complexity can mask issues and make it challenging to ensure the integrity of the water system and to keep the trust of the employees.

Similarly, hospital campuses exemplify this complexity on a grand scale. Multiple buildings cater to various healthcare functions, each with specific water quality requirements. The interconnection of these buildings’ water systems necessitates rigorous monitoring and maintenance. Any lapse can have severe consequences, not just for potable water but for the sterile environments crucial in healthcare settings.

Food processing plants also face a unique set of challenges. Here, water quality directly impacts product safety and compliance with stringent health regulations. The complexity of the water infrastructure, coupled with the need for absolute hygiene, makes it imperative that every segment of the system functions flawlessly. Yet, the sheer scale and interconnectivity often lead to uncertainties and hesitations.

The Impact of Unknowns

The primary driver of mistrust is not a lack of faith in the water’s source or the competence of the maintenance teams but the inherent unknowns within the system. Employees are acutely aware that the infrastructure is a patchwork of old and new, simple and complex, and known and unknown elements. This awareness breeds caution.

In many cases, it’s not a specific incident but the potential for issues that fuel this caution. The thought that “you must know exactly what connects to the water system” underscores the anxiety surrounding the unknowns. Employees prefer bottled water, which offers a guaranteed standard of safety, over the uncertain quality of the tap water, which might be subject to unseen contamination or degradation.

Addressing the Issue

A critical first step in addressing the mistrust in facility water systems is conducting a comprehensive onsite survey and audit. This process involves a detailed inspection of the entire water infrastructure, identifying potential problem areas, outdated components, and points of vulnerability. By thoroughly mapping the existing system, maintenance teams can gain a clear understanding of the current state of the infrastructure.

Generating up-to-date piping schematics out of this survey is equally essential. Many industrial facilities rely on outdated or incomplete diagrams, which contribute to the uncertainty and complexity of the water system. Accurate, current schematics provide a visual representation of the entire network, highlighting connections, flow directions, and critical nodes. This clarity allows for better planning, more effective maintenance, and quicker identification of issues.

By combining onsite surveys with updated schematics, facilities can proactively address potential risks. These measures not only enhance the maintenance team’s ability to manage the system but also provide a foundation for future upgrades and improvements. Furthermore, sharing these efforts with employees can significantly increase transparency and trust, reassuring them that the facility is committed to providing safe and reliable water.

Conclusion

The reluctance of employees to drink from facility water fountains is a symptom of a deeper issue: the complexity and perceived unreliability of the water infrastructure. Addressing this requires acknowledging the legitimate concerns and working proactively to simplify, monitor, and communicate the safety of the water system with new piping schematics that are regularly updated. By doing so, facilities can not only ensure the well-being of their employees but also build the trust that is essential for a healthy workplace.