Snapshot

Legionella, the bacteria responsible for Legionnaires’ disease, thrives in stagnant, warm water—making building water systems particularly vulnerable if not carefully monitored and maintained. One of the most effective preventive strategies in managing the risk of Legionella proliferation is the regular visual surveying of potable water piping systems. Visual surveys with documentation on reliable piping schematics are crucial for identifying high-risk configurations, such as dead-end legs and poorly designed loops, that can become breeding grounds for harmful bacteria.

The Practical Guide to Piping Schematics

Understanding Dead-End Leg Piping: A Hidden Risk

Dead-end leg piping refers to sections of the piping system where water flow is minimal or nonexistent. These pipes can be the result of outdated designs, renovations, or changes in a building’s plumbing layout that leave behind unused sections of pipe. Water stagnates in these areas, creating an ideal environment for Legionella to grow, especially when temperatures rise above 68°F (20°C).

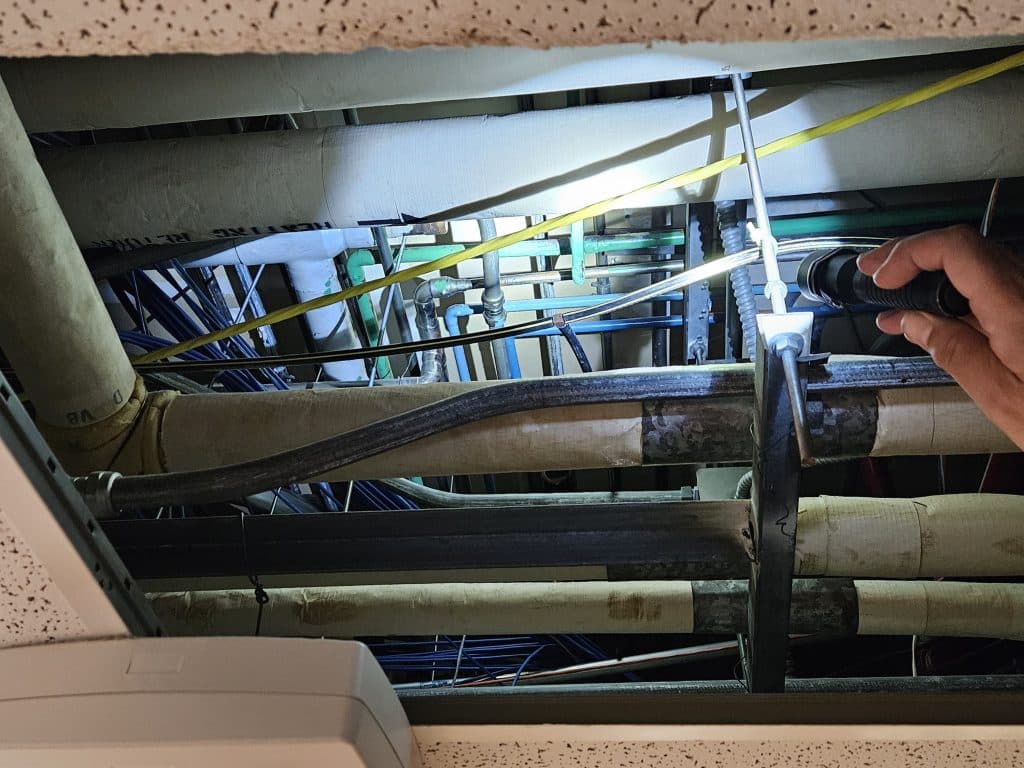

During a visual survey, piping surveyors physically assess and document all visible sections of the potable water system to identify these dead-end legs. By locating these high-risk areas, facilities can take action to either remove, flush, or treat these dead sections of piping, dramatically reducing the risk of bacterial buildup. Periodic piping system surveys that also update or create accurate schematics can enable long-term ease of system maintenance and monitoring of piping conditions.

Other High-Risk Configurations for Legionella Proliferation

Beyond dead-end piping, other piping configurations can also pose a serious risk for Legionella outbreaks. These include:

- Loops with Poor Water Flow: In complex building plumbing systems, water may flow unevenly, creating areas where water can sit stagnant for long periods. Identifying these problematic loops through visual surveys helps to mitigate stagnation and prevent bacterial growth.

- Areas Near Heat Sources: Pipes located near boilers, hot water tanks, or other sources of heat are more susceptible to Legionella, as the bacteria thrive in temperatures between 68°F and 122°F (20°C to 50°C). Piping surveys can identify these areas, allowing for adjustments to insulation or rerouting.

- Oversized Piping for Reduced Demand: Some older buildings may have oversized pipes relative to their current water demand, leading to stagnation in underused sections of the system. Visual surveys can pinpoint these sections, prompting the facility to consider downsizing pipes or increasing water circulation to prevent issues.

Visual Surveys as Part of a Legionella Control Program

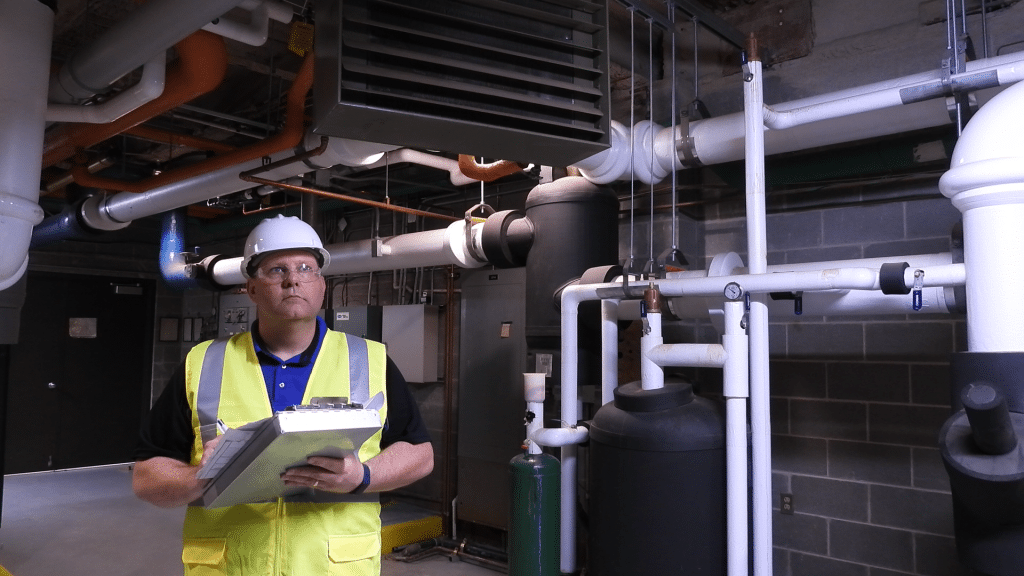

A comprehensive Legionella control program integrates visual piping surveys into regular maintenance schedules, combining them with water temperature monitoring, biocide treatments, and system flushing protocols. By routinely inspecting the piping layout, facility managers can detect hidden risks before they escalate into full-scale outbreaks.

In addition to identifying high-risk configurations, visual surveys and reliable piping schematics also allow facility teams to assess the overall condition of the piping system. Corrosion, leaks, or poorly maintained pipe joints can further exacerbate the risk of Legionella by encouraging bacterial growth in moist environments.

Immediate Benefits of Regular Piping Surveys

Conducting visual surveys offers several immediate benefits for facilities that prioritize the health and safety of their water systems:

- Early Risk Detection: By identifying potential problem areas early, facilities can act proactively to prevent bacterial growth, rather than react to an outbreak.

- Enable Reliable Piping Schematics: During the survey, piping schematics and associated connections, valve locations, diameters and backflow preventers can be documented for cost-reducing maintenance and contractor planning.

- Cost-Effective Maintenance: Addressing dead-end legs and other risk factors before they cause widespread contamination can save significant costs associated with emergency remediation, system downtimes, or legal liabilities due to health risks.

- Compliance and Confidence: Many regulatory bodies, including OSHA and the CDC, recommend or require active Legionella prevention programs in large facilities. Regular visual surveys help ensure compliance with these regulations, offering peace of mind for building managers, healthcare institutions, and manufacturers.

Conclusion

Protecting Water Systems from Legionella Regular visual surveys of potable water piping are a critical part of any facility’s water safety plan. By identifying dead-end legs, stagnant loops, and other high-risk areas, facilities can take swift action to ensure their water systems remain safe, clean, and free of dangerous bacteria like Legionella.

Maintaining healthy water systems through vigilant monitoring and proactive adjustments isn’t just about regulatory compliance—it’s about safeguarding public health and providing confidence in the quality of the water flowing through every tap.