Top 10 Piping Issues Facing Healthcare Facilities & How to Solve Them

Summary:

- Piping schematics and P&ID (Piping & Instrumentation Diagrams) are vital tools for healthcare facility managers and maintenance supervisors, providing a crucial overview of their piping systems and guiding quick responses during emergencies, minimizing downtime, and enhancing overall operational efficiency.

- By updating these schematics or diagrams regularly, they enable proactive risk mitigation by clearly documenting every detail of any piping system, especially in the case of system and/or facility addition or/or expansion.

- Beyond crisis management, accurate schematics contribute to overall emergency preparedness, ensuring that maintenance employees are well-versed in the hospital’s infrastructure for a coordinated and effective response during high-stress emergency situations.

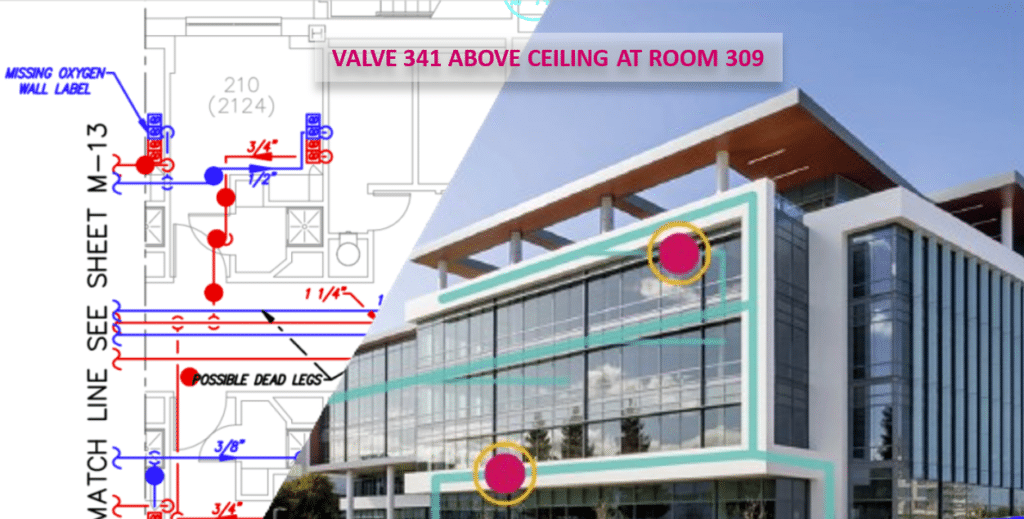

As any healthcare facility manager or maintenance supervisor could tell you, emergency breakdowns involving the building’s infrastructure will inevitably arise, putting the lives of patients and others at risk. Whether there is faulty medical gas valve above tile or potable water contamination from backflow, these issues need action – and fast – to mitigate any potential health risks or facility damage. An efficient emergency response relies on having the proper information readily available to direct maintenance and repair crews directly to the source of the problem and to the solution.

Here’s how having and maintaining updated, as-installed piping schematics and P&ID of all your piping systems in your hospital leads to a highly effective emergency response to any piping problems:

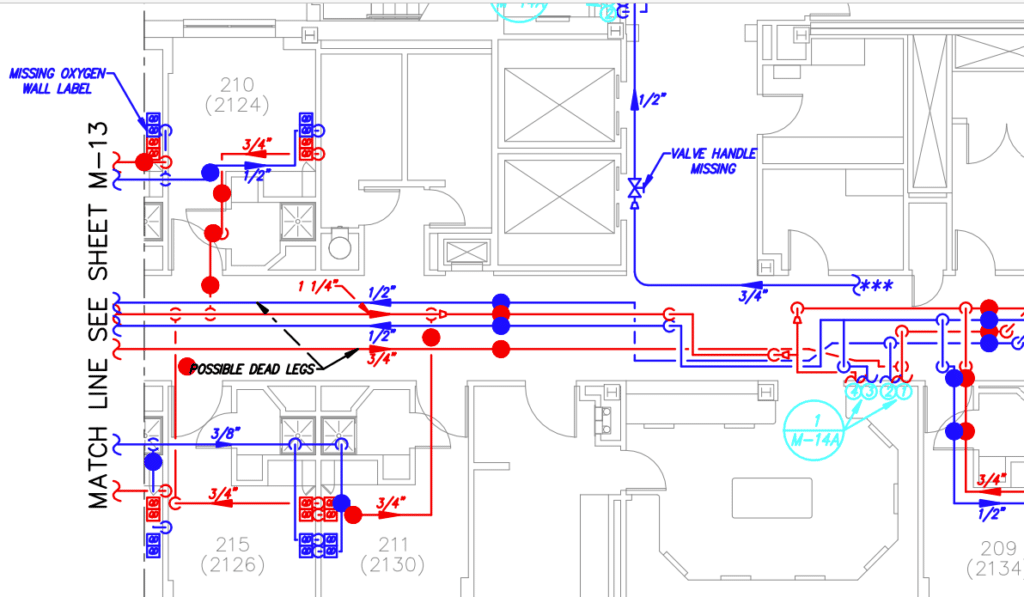

1. Outdated Piping Schematics Disadvantage Hospital Operations

Maintenance and safety protocols become hindered when piping schematics are unreliable. Accurate piping schematics serve as the foundation for a facility’s infrastructure management. Having precise schematics of all a facility’s piping systems is like having a roadmap to navigate through crises. These diagrams provide a visual representation of the intricate network of pipes, valves, and connections, offering a comprehensive overview of the facility’s plumbing and medical gas systems. Furthermore, as buildings expand or different areas of the hospital are repurposed or new medical equipment is brought in, piping systems change along with them. This requires maintaining up-to-date schematics by conducting surveys routinely and ensuring that the schematics represent the current systems accurately.

Potable Water Plumbing

In a hospital setting, ensuring a safe and reliable water supply is paramount. Accurate potable water plumbing schematics empower facility and maintenance managers to quickly identify the main water lines, shut-off valves, and potential points of contamination in the form of cross-connections. While these should all be isolated by backflow preventers, being able to pinpoint the location of these assemblies is critical. When experiencing a water main break or backflow incident, having detailed schematics allows for efficient isolation of affected areas and the rapid implementation of corrective measures. This proactive approach not only mitigates risks to occupants but also safeguards the integrity of the facility’s water supply, avoiding crises that could endanger patients or cause employee illness.

Medical Gas Piping

Having accurate and up-to-date piping schematics of medical gas piping in a hospital is critical for facility managers and maintenance supervisors. These schematics provide a comprehensive overview of the intricate network of medical gas pipelines, valves, and connections throughout the facility. During emergencies such as power outages, natural disasters, or medical emergencies, quick and precise access to medical gas supplies can be a matter of life and death. Accurate piping schematics enabling staff to swiftly identify the location of medical gas lines, shut-off valves, and distribution points, ensuring a rapid response to critical situations. Moreover, in situations where repairs or maintenance are required, detailed schematics facilitate efficient troubleshooting and restoration of medical gas services. By having a clear understanding of the piping layout, maintenance teams can expedite repairs, minimize disruptions to medical gas supply, and maintain the continuity of patient care.

2. Enhancing Emergency Preparedness

Accurate piping schematics and P&ID are not just tools for crisis management; they are crucial elements of a hospital’s overall emergency preparedness plan. Regularly updated schematics provide an ongoing snapshot of the facility’s infrastructure, aiding in the identification of vulnerabilities and potential risks. This ensures that hospitals and other healthcare facilities are not just reacting to crises but are proactively mitigating risks and safeguarding against potential disasters, especially when it comes to adding new piping systems or expanding existing systems.

3. Enable Your Maintenance Team

In emergency situations, time is a critical factor. In a hospital setting, it can be a matter of life and death. Having a well-trained response team familiar with medical gas, potable water, and other piping systems can make all the difference. Regular training sessions that involve hands-on familiarization with the schematics, including recognizing legend symbols and knowing where the schematics are kept, enable response teams to quickly locate essential components and take decisive actions. This ensures a coordinated and effective response during high-stress situations that can mitigate risks to patient or staff wellbeing, system functionality, and facility conditions.

Call To Action

When it comes to outlining emergency response plans for any issues or breakdowns in piping systems, accurate and up-to-date piping schematics emerge as indispensable tools for healthcare facility managers and maintenance supervisors. These blueprints not only guide responses in times of crisis but also serve as proactive instruments for risk mitigation when updated regularly. Detailed schematics and diagrams ensure that facilities navigate emergencies with precision, resilience, and a commitment to the safety and wellbeing of patients and staff.