Top Takeaways

- Even with a cross-connection control program in place, all too often, gaps between the law and enforcement actions can be great

- It is important to examine every aspect of your cross-connection control program to achieve true compliance

- This list of 10 common gaps are only the key places to start

Gaps in Cross-Connection Control Programs & How to Fill Them

The gap between what state regulations actually require compared to what is “enforced” is a gap of potential contamination, risk, and liability for public water systems. Cross-connection control programs play a crucial role in preventing contamination of drinking water supplies by identifying and mitigating potential cross-connections. However, many programs face significant gaps that hinder their effectiveness and true compliance with state regulations on controlling cross-connections and backflow hazards. Here are ten common gaps and actionable steps to fill them, making your local cross-connection control program more robust and compliant: Read our article below or watch our webinar on the topic!

1. No established/adopted cross-connection control program plan

Without a formal plan, it’s challenging to ensure consistent and effective cross- connection control. Start by developing a written plan that aligns with state regulations and plumbing codes. Make sure this plan is formally adopted by the relevant authority or governing body. Regularly review and update the plan to reflect any changes in regulations or operational practices.

2. Insufficient budget for true compliance approach

To address any potential shortcomings while budgeting for cross-connection control, it’s essential to first conduct a thorough budget analysis. This analysis should identify all current costs associated with these activities. Additionally, exploring additional funding sources, such as grants, state funding, or reallocating existing budgets, can provide necessary financial support. Furthermore, obtaining cost proposals from qualified vendors that meet all state regulation requirements is crucial to ensure comprehensive compliance.

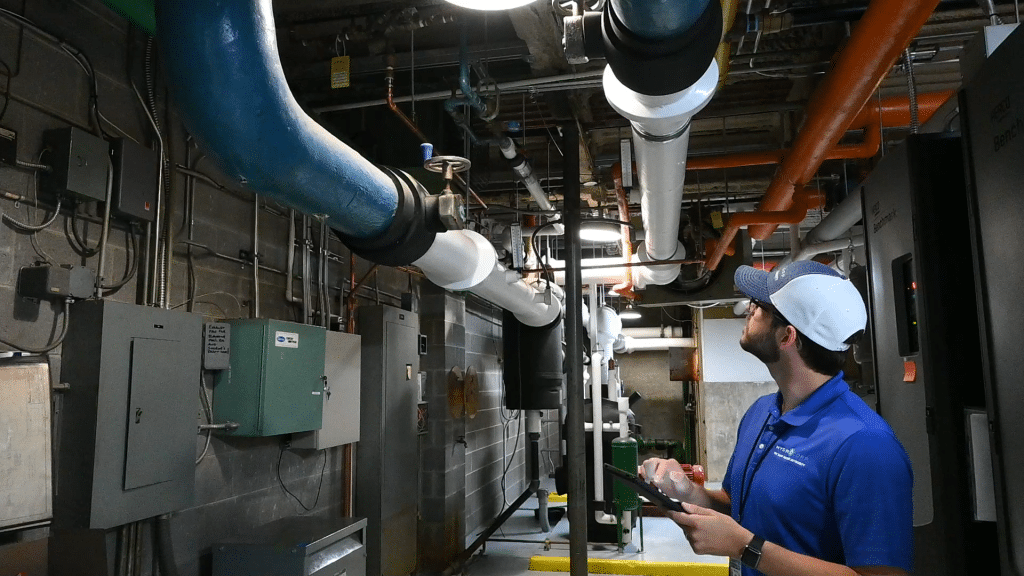

3. Not all Backflow Preventer Assemblies locations are known

Locating and documenting all backflow preventer assemblies that are connected to the water system is only possible with a comprehensive onsite visual survey process. These surveys should identify all service containment backflow assemblies and, if applicable, internal backflow prevention devices or methods at all potable water points of use. Following the identification process, a centralized database should be developed to track and manage all identified backflow preventer locations. Regular updates to this database are essential to ensure it remains accurate and up to date.

4. Limited process to identify/survey for existing cross-connections

Implementing a process for regular visual surveys of service connections and areas without containment backflow preventers is essential, as relying on building owner self-surveys may result in unreliable data. Staff should be trained on effective survey techniques and provided with the necessary tools and resources. Additionally, establishing a schedule for routine surveys and follow-up inspections will ensure consistent monitoring and accuracy.

5. Relying solely on software for entire cross-connection program

To ensure comprehensive program management, it is important to integrate software solutions with regular physical inspections and human oversight. Assigning a dedicated person to oversee onsite activities and facilitate direct engagement with building owners is also crucial. Regularly reviewing software data and cross-referencing it with field inspections will help identify any discrepancies and maintain accuracy.

6. Lack of enforcement to resolve identified backflow hazards

Addressing identified backflow hazards requires the development of clear enforcement policies and procedures. Establishing a straightforward sequence for notifying building owners about non-compliance issues is also necessary for effective enforcement. Communicating these enforcement policies to the public and building owners will help mandate compliance and ensure everyone is aware of the requirements.

7. Untrained staff are not able to identify common cross-connections

Developing a comprehensive training program for staff is crucial for identifying common cross-connections and understanding their associated risks. Partnering with industry experts or organizations can provide specialized training sessions on cross-connection control practices, enhancing the staff’s expertise. Additionally, implementing ongoing training and professional development ensures that staff knowledge remains current and effective.

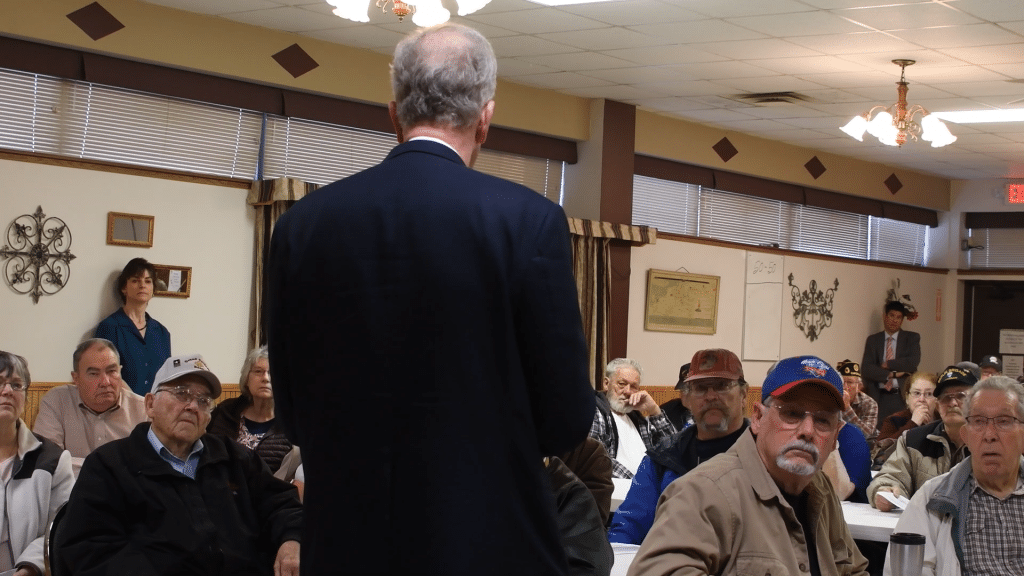

8. Council/Commission does not support corrective action activities

Engaging with council and commission members is essential to educate them on the importance of cross-connection control, its impact on public health, and the requirements needed for state compliance. Presenting case studies and data can effectively demonstrate the risks associated with non-compliance and the benefits of supporting corrective actions. Collaborating with stakeholders to develop a comprehensive approach will further strengthen the effort to address these issues.

9. Backflow test records are the extent of current program

Expanding the program to include regular visual inspections, surveys, and public awareness initiatives, alongside backflow test records, is vital for comprehensive cross-connection control. Implementing a robust record-keeping system that tracks all aspects of the program will enhance management and oversight. Regularly reviewing and analyzing these records can help identify trends and areas for improvement, ensuring the program’s effectiveness and ongoing refinement.

10. Uncertainty of what exactly to do for true compliance

Hiring a specialized cross-connection consulting vendor to conduct a thorough compliance audit is necessary for identifying specific areas where the program may be lacking. Based on the audit’s findings, a detailed action plan should be developed, outlining steps to achieve full compliance, including timelines and responsible parties. Additionally, providing ongoing education and resources to staff and stakeholders is important to ensure they fully understand and adhere to the compliance requirements.

For any further help improving your cross-connection control program, contact HydroCorp for a free consultation!