It’s not about being Right, it’s about being Referenceable

- When talking about backflow prevention, exact and accurate communication is critical

- Even professionals in the industry can fall into the traps of these common errors

- Correct communication is incredibly important when it comes to correcting action requirements for water customers

- Using the correct terms, words, and standards align your communication to referenceable resources

Cross-Connection Control vs. Backflow Prevention: What’s the Difference?

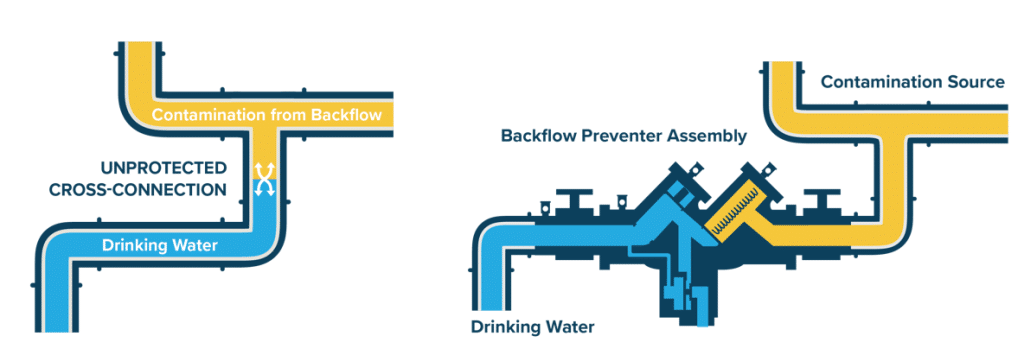

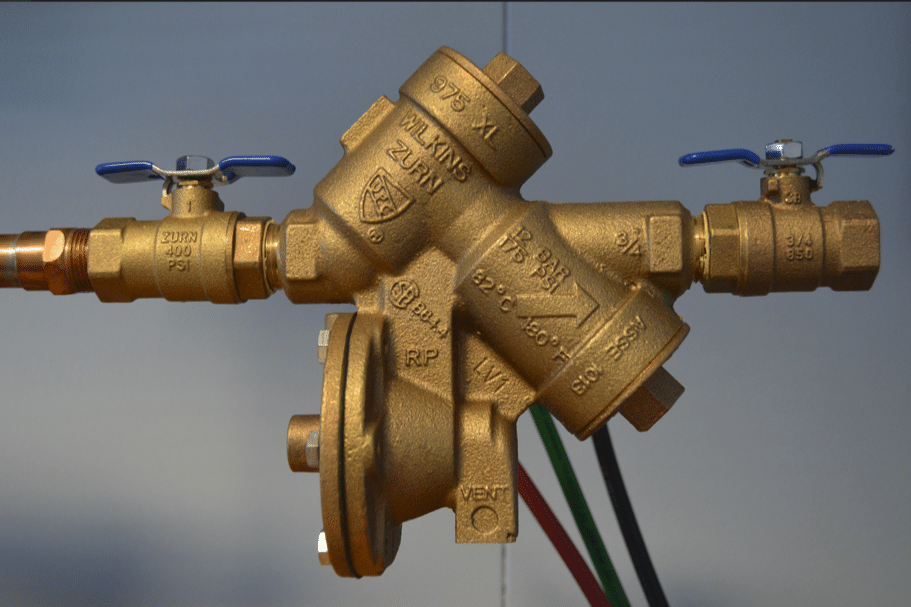

Image on right is a properly isolated cross connection to the potable water piping by installation of an ASSE 1013 type backflow prevention assembly recently tested by a state certified backflow preventer assembly tester

Conveying accurate and understandable details or referenceable corrective action instructions to building owners can be one of the biggest burdens of cross-connection control program requirements for public water systems. In the world of backflow prevention and cross-connection control for potable water systems, terminology and exact phrasing are crucial. However, even professionals sometimes fall into the trap of using incorrect phrases, acronyms, and words. Let’s dive into some common misused words and terms to clarify and ensure accurate and consistent communication in this essential field.

“Test All Your Cross-Connects”

The phrase “test all your cross-connects” is a common, yet inaccurate, expression. A cross-connection is any actual or potential connection between a potable (drinking) water supply and a non-potable source. Instead of testing cross-connections, we should focus on identifying and protecting them. Tests should be performed on Backflow Prevention Assemblies which are mechanical assemblies used to isolate hazardous cross-connections.

Correct Approach:

- Identify Cross-Connections: Conduct a thorough survey to locate all potential cross-connections within the water system.

- Protect Cross-Connections: Use appropriate backflow prevention devices or assemblies to protect identified cross-connections. Be sure that the testable backflow prevention assemblies are tested on a regular basis.

“Install a Backflow”

Another frequently heard term is “install a backflow.” This phrase is misleading as it suggests that “backflow” is a device. Backflow is the undesirable reversal of flow in a potable water distribution system, potentially causing contamination. What needs to be installed is a backflow prevention device or assembly.

Correct Approach:

- Install a Backflow Prevention Device or Assembly: Specify the type of device needed, such as a Reduced Pressure Zone (RPZ) assembly, Double Check Valve Assembly (DCVA), or Pressure Vacuum Breaker (PVB).

“Portable Water”

There is often confusion between the terms “portable water” and “potable water.” However, “portable water” is not a correct term and doesn’t mean anything specific. The accurate term to use is “potable water,” which refers to water that is safe for human consumption.

Correct Usage:

- Potable Water: Always use “potable” when referring to water that is safe to drink.

“Inspect Your Backflow”

The phrase “inspect your backflow” can be confusing. It’s important to clarify that inspections should be conducted on backflow prevention devices or assemblies, not “backflow” itself.

Correct Approach:

- Inspect Backflow Prevention Devices, Assemblies, and Methods: Regular inspections and testing of backflow prevention devices and assemblies are essential to ensure they function correctly and protect the potable water supply.

“Put in a Check Valve”

The term “put in a check valve” is often incorrectly used to imply a solution for all backflow prevention needs. While check valves are components used in backflow prevention devices, they alone are not sufficient for preventing backflow.

Correct Approach:

- Install the Appropriate Protection: Each connection should be evaluated on its own. Depending on the level of hazard, an RPZ assembly, DCVA, PVB, or a simple Air Gap may be required, but there is not a single supported use case for installing a single check valve as a method of backflow prevention.

“Hose Backflow”

The phrase “hose backflow” is vague and misleading. It may refer to backflow through a hose connection, rather than the device used to prevent backflow through a hose connection.

Correct Approach:

- Use Hose Bibb Vacuum Breakers: Install hose bibb vacuum breakers on all exterior hose connections to prevent backflow through hoses.

“Backflow Inspector”

The term “backflow inspector” is commonly used, but the correct designation is often “cross-connection control inspector” or “backflow prevention assembly tester”, depending on the work that they do.

Correct Approach:

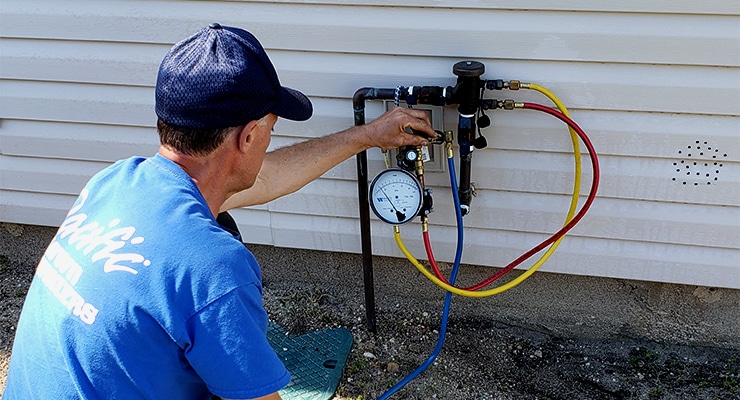

- Use Accurate Titles: Refer to professionals as “cross-connection control inspectors” if they are conducting a point-of-use survey or “backflow prevention assembly testers” if they are trained to test backflow prevention assemblies with a pressure differential gauge. This reflects their specific roles and acknowledges the certifications or training that each respective position requires.

“Backflow Program”

The term “backflow program” is frequently used interchangeably with “cross-connection control program,” but they are not the same. A cross-connection control program encompasses all aspects of preventing backflow, including identifying cross-connections, tracking backflow preventer tests, corrective action enforcement, and implementing other protective measures.

Correct Approach:

- Use “Cross-Connection Control Program”: This term accurately reflects the comprehensive nature of programs that aim to prevent backflow, manage cross-connections, and spread public awareness about this critical water safety issue.

“Backflow Protector”

The term “backflow protector” is vague and does not specify the type of device or assembly used for backflow prevention.

Correct Approach:

- Specify the Device or Assembly: Use terms like “RPZ assembly,” “DCVA,” or “PVB” to indicate the specific backflow prevention device or assembly being referred to. Another method to specify the device or assembly is to refer to the ASSE number, which is a standard number stamped onto approved backflow prevention devices and assemblies. For example, and approved PVB has the corresponding ASSE number of ASSE #1020.

“EPA Required Backflow Program”

The claim that the EPA requires a backflow program is incorrect. While the EPA sets national drinking water standards, backflow prevention and cross-connection control programs are mandated and enforced at the state and local levels. The EPA has no federal requirements for the implementation and management of a cross-connection control program.

Correct Approach:

- Acknowledge State Regulatory Authority: Recognize that backflow prevention requirements are typically addressed through state adopted plumbing codes and cross-connection control requirements are usually established by state administrative codes governing public water systems. Refer to these requirements when creating or revamping your cross-connection control program for backflow prevention monitoring, enforcement, and tracking activities.

“RPZ”

The acronym “RPZ” or “RP” stands for Reduced Pressure Zone, a type of backflow prevention assembly. Understanding the specific function and application of an RPZ is crucial for proper terminology and implementation. RPZ is not a catch-all descriptor off all backflow prevention devices or assemblies.

What is an RPZ?

- Reduced Pressure Zone Assembly: An RPZ is a backflow prevention assembly that provides high-level protection against backflow caused by both backpressure and backsiphonage. It consists of two independent check valves and a pressure differential relief valve. The proper name according to ASSE Standards is “Reduced Pressure Principle (Zone) Backflow Prevention Assembly”, and has an ASSE Standard number 1013.

Correct Application:

- Use Reduced Pressure Principle Backflow Prevention Assemblies Where Required: RPZ assemblies are typically required in high-hazard situations where the potential contamination risk is significant. In select states, they can be used as a containment device, allowing the building owner to install the assembly at the service line directly after the meter. An accurate way to document and reference this assembly is to cite it by “ASSE number 1013”. Example: “Facility owner is required to have an ASSE 1013 type backflow preventer assembly install in direct supply line to chemically treated boiler system in sour west boiler room of hospital”.

Wrap Up

Clear and accurate communication is vital in backflow prevention and cross-connection control. By understanding and using the correct terminology, professionals can better protect potable water supplies and ensure public health and safety. Avoiding common gaffes like “install a backflow,” “portable water,” put in a check valve,” or “backflow program,” will help maintain clarity and effectiveness in the field. Recognizing that backflow prevention requirements are typically managed at the state and local levels, rather than by the EPA, further ensures accurate and effective implementation of cross-connection control programs.