Steps to Creating Accurate Schematics:

Creating accurate piping system schematics involves several key steps that can be summarized in these two phases:

- Phase 1: Gather relevant information about the system, including design drawings, equipment specifications, and any existing piping schematics or floor plan drawing.

- Phase 2: Perform a thorough field survey to verify the actual installation and collect data on pipe sizes, lengths, fittings, and equipment locations. This information is then used to create the initial or updated schematic using specialized software or drafting tools.

Read on for a detailed and thorough outline of these phases to learn how reliable hospital piping schematics are made!

Top 10 Piping Issues Facing Healthcare Facilities & How to Solve Them

The Importance of Accurate Piping Schematics

As a CHFM or administrator of a healthcare facility, ensuring the safety of everyone in your building is a top priority. This involves protecting the integrity of your critical piping systems that convey potable water and medical gases throughout the facility. These systems are essential for serving patients and supporting medical processes. However, maintaining and monitoring these infrastructures is no small feat, and emergencies such as a legionella outbreak, cross-connection contamination, or mechanical damage can quickly escalate the challenges you face daily.

When an urgent issue arises in your facility’s potable water system or medical gas piping, having reliable and up-to-date piping schematics is crucial. Incomplete or outdated blueprints can hinder your ability to address problems swiftly and effectively. It can lead to costly delays as staff spends hours locating leaks through trial-and-error valve closures. Additionally, any changes made to the plumbing since the original construction can further complicate the situation if not accurately documented. Therefore, reliable piping schematics are not just helpful; they are essential for effective system management and compliance with industry standards.

Accurate piping schematics are foundational for the efficient and safe operation of healthcare facilities. They provide a detailed map of your piping systems, offering critical information that supports maintenance, emergency response, and regulatory compliance. Here’s why having precise and up-to-date schematics is indispensable:

- Enhanced Safety: Knowing the exact layout of your piping systems enables swift isolation and remediation of areas affected by contamination issues such as legionella outbreaks or cross-connections.

- Efficient Problem-Solving: With detailed schematics, staff can locate leaks and other issues without resorting to trial-and-error methods, saving valuable time and resources during emergencies.

- Regulatory Compliance: Meeting the stringent requirements of organizations such as the Centers for Medicare & Medicaid Services (CMS) and the Joint Commission is crucial. Reliable schematics ensure your facility complies with these standards, which often require detailed documentation of piping systems.

- Maintenance and Upgrades: Whether for routine maintenance or upgrades, accurate schematics provide the information needed to plan and execute work efficiently, minimizing disruption to facility operations.

Creating Accurate Piping Schematics

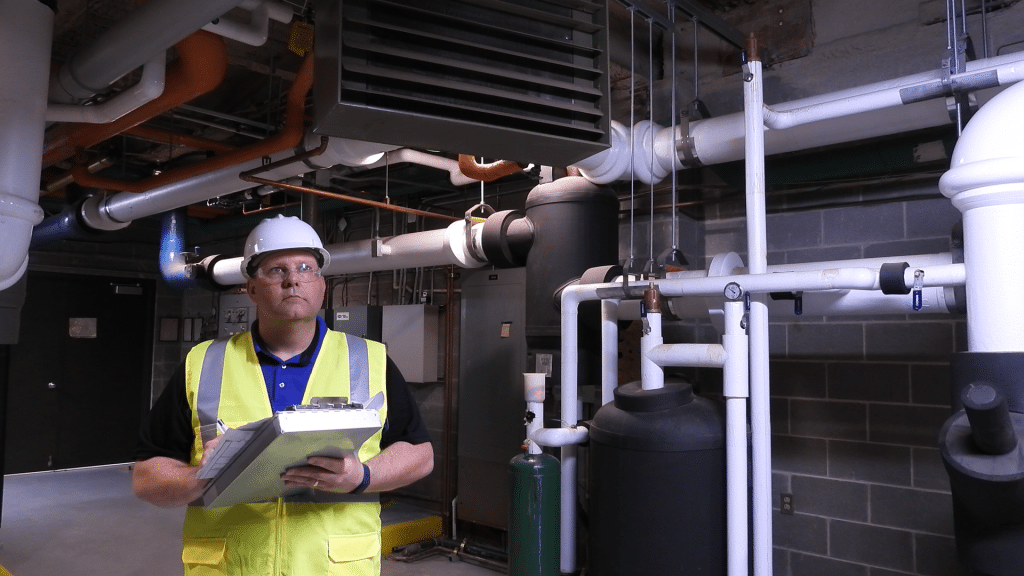

The process of creating accurate piping schematics involves the meticulous visual tracing of every inch of the piping system. This comprehensive method includes:

- Visual Inspection: Beginning at the service connection, surveyors must be able to climb ladders, lift ceiling tiles, and trace pipes throughout the facility to each end-use point. While laborious and time-consuming, this thorough method is the only way to accurately document the real-world conditions of each piping system.

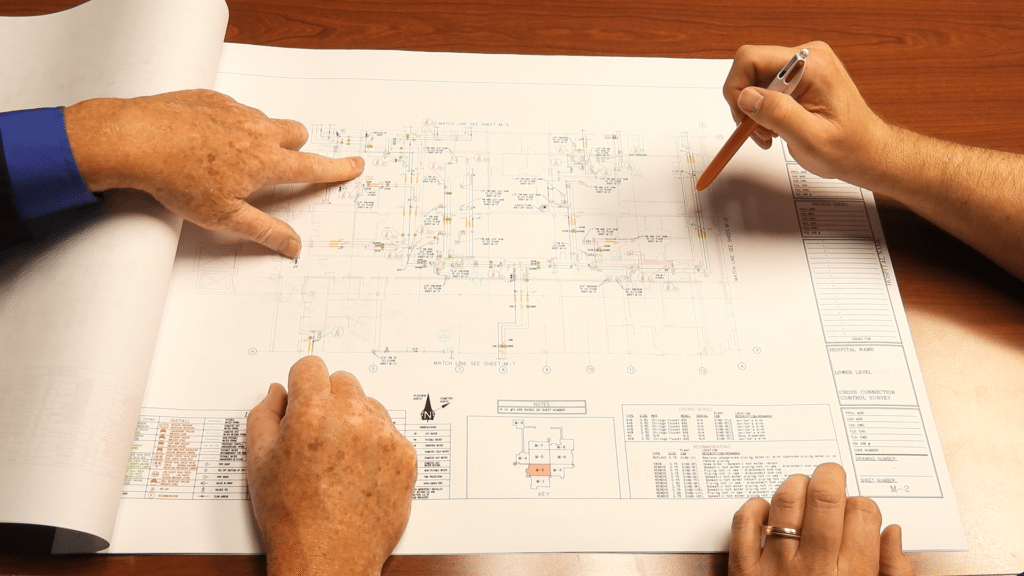

- Field Drawings: During the visual inspection, the surveyor will be rendering detailed field drawings that capture the current state of the piping system, including pipe diameter, flow direction, labels, shut-off valves, plumbing components, and end points. All of this information is critical to capture and requires a trained professional to accurately identify each piece of data.

- Assessment and Documentation: Assessing whether the current system meets appropriate codes and standards. If there are any connections or fixtures that are not up to snuff, corrective action requirements must be made in detail to instruct construction crews/plumbers to fix the issue. The surveyor may also make recommendations to optimize and update the system. The collected data should be processed into digital, up-to-date documentation, so the surveyor’s hand drawn sketches and notes are not the only source of this vital information that has been collected.

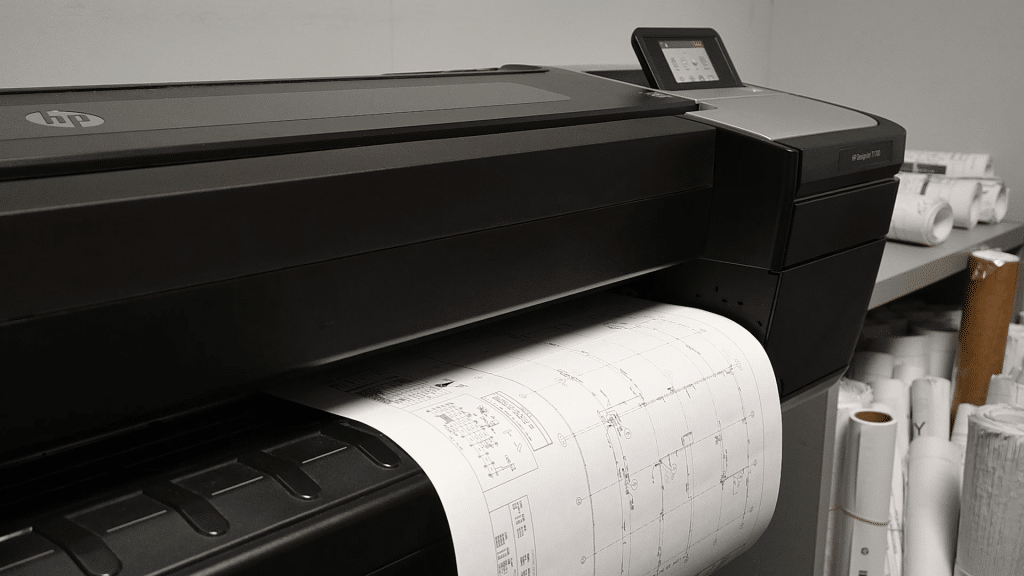

- Detail and Clarity: Schematics should be highly detailed, clearly showing all aspects of the piping system. Different systems should be color-coded for easy distinction on a single drawing. This is another benefit of processing the collected data into a digital format using a CAD system.

Utilizing Piping Schematics

Once created, these piping schematics serve multiple purposes:

- Operational Awareness: Facility staff can rely on schematics for a comprehensive understanding of the piping infrastructure, aiding in daily operations and emergency responses.

- Training and Education: New staff can be trained more effectively with accurate visual aids, ensuring they understand the layout and critical points of the piping systems.

- Regulatory Inspections: During inspections, detailed schematics can be provided to demonstrate compliance with health and safety regulations, providing evidence of diligent infrastructure management.

- Maintenance Scheduling: Regular maintenance can be better planned and executed with clear schematics, reducing the risk of unexpected issues and downtime.

Wrapping It Up

In healthcare facilities, the safety of patients and staff hinges on the reliability of critical systems like potable water and medical gas piping. Accurate and up-to-date piping schematics of these systems are essential tools that enhance safety, streamline problem-solving, and ensure regulatory compliance. By investing in the meticulous process of creating and maintaining these schematics, healthcare facility managers can ensure their infrastructures are robust, resilient, and ready to meet any challenge. Reliable schematics mean safe patients, efficient operations, and a facility that stands up to the highest standards of care and safety.