Summary

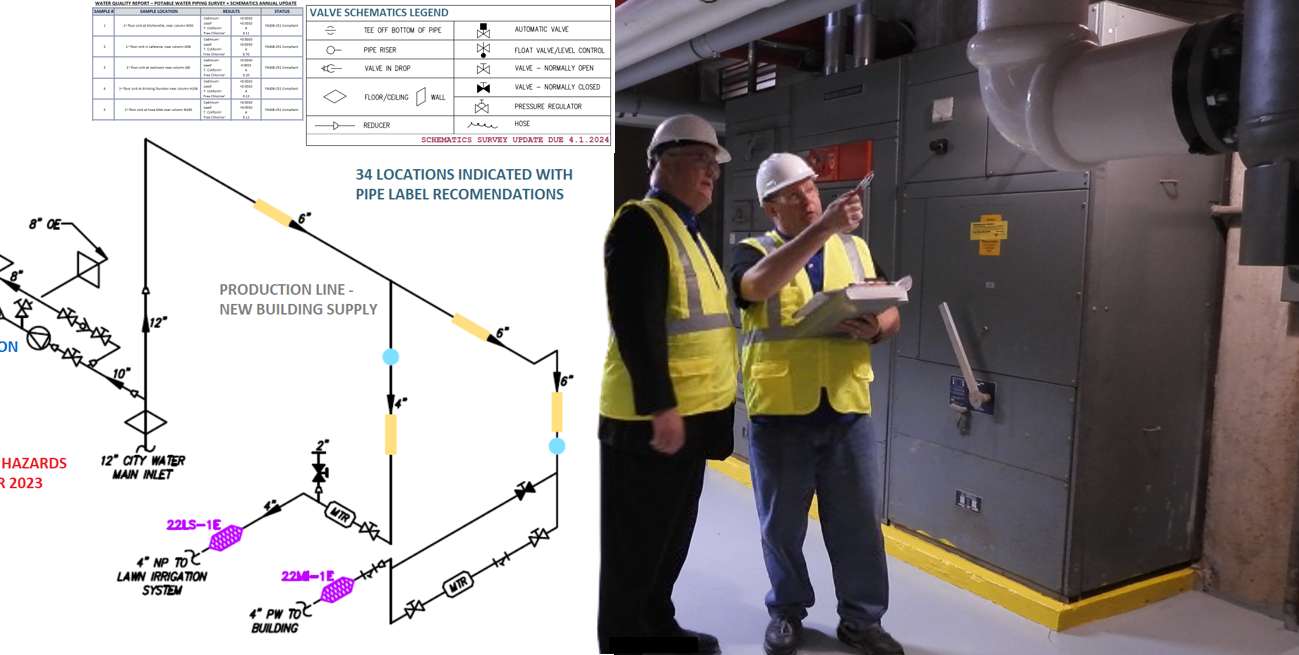

- Periodically updating a hospital’s piping schematics yields a wealth of benefits for healthcare facility managers and maintenance workers by staying current to any physical, real-world changes to the facility’s infrastructure.

- Having up to date schematics for facility management and maintenance teams for piping systems such as potable water and medical gas enables a rapid response to emergencies, reducing downtime and mitigating any risk to patients and staff.

- Other benefits include regulatory compliance, long-term cost savings, and, in the case of digitized CAD schematics, adaptability for the future.

Piping schematics are an often overlooked yet vital component of healthcare facility management and maintenance, particularly as it pertains to the safety and health of employees and patients in a hospital. These intricate diagrams serve as the blueprint for the labyrinth of pipes carrying essential resources like potable water and medical gases throughout healthcare facilities. Details including shut off valves, temperature control valves, pressure regulators, and more should be included on these documents for ease of access and information sharing. Yet, all too often, these schematics become outdated and inaccurate, failing to reflect any updates to the building, changes to the piping systems, or removal of equipment. Sometimes, the only copies of a hospital’s schematics in existence are the hard paper copies that were generated when the facility was built! It’s time to change this narrative. Let’s normalize the periodic updating of piping schematics, as making this a regular practice underpins safety, efficiency, and reliability within hospital infrastructure.

Updated Schematics for Updated Piping

One of the most crucial aspects of piping intel is the need for hospitals to stay current with facility modifications, demolitions, or additions. Hospitals and other healthcare facilities are constantly evolving, with renovations, expansions, and upgrades being commonplace occurrences. Between adding a new wing, installing new equipment that will be hooked up to the potable water system or the medical gas system, and the removal of piping infrastructure that can result in dead leg piping, the changes don’t stop coming. Failure to reflect these changes in piping schematics can lead to confusion and potentially dangerous situations. Imagine a scenario where an outdated schematic misguides maintenance personnel to a non-existent pipe or valve. Such errors can result in delays in critical maintenance tasks or even worse, compromise the integrity of essential systems.

Ensuring safety across all piping systems, including potable water and medical gas, is paramount in healthcare facilities. Potable water serves as a lifeline, indispensable for patient care, sanitation, and medical procedures. Medical gases, on the other hand, are instrumental in various treatments and life support systems. Gases like Oxygen are also combustible and need to be handled with extreme care. Any unforeseen issues in these systems can have grave consequences, especially if the schematics for the system in question are not accurate or up to date. Updated piping schematics provide a clear and accurate representation of these intricate and complex piping networks, aiding in the identification of potential hazards and ensuring compliance with safety regulations. Whether it’s stopping a leak, preventing contamination, or facilitating swift responses during emergencies, the significance of updated schematics cannot be overstated in safeguarding the well-being of patients and staff alike.

Streamlining Maintenance Operations and Regulatory Compliance

Moreover, consistency and reliability are the cornerstones of effective maintenance operations. Maintenance teams and facility management teams are the unsung heroes who keep hospital infrastructure running smoothly for the nurses and doctors. However, their effectiveness hinges upon the availability of accurate information. Outdated or inaccurate schematics can lead to confusion, inefficiencies, increased downtime, and potentially the impediment of lifesaving actions. By normalizing the periodic updating of piping schematics, hospitals empower their maintenance teams with the tools they need to perform their duties effectively. By digitizing these updates, schematics can be accessed by anyone on staff with a computer, without having to rely on single physical copies. Access to reliable schematics ensures that maintenance tasks are carried out with precision, reducing the likelihood of errors and minimizing disruptions to essential services.

Embracing the practice of periodic updates also aligns with broader initiatives aimed at enhancing operational efficiency and regulatory compliance. In an era where healthcare organizations face increasing scrutiny and accountability, maintaining accurate documentation is non-negotiable. Updated piping schematics serve as a testament to a hospital’s commitment to excellence in infrastructure management and asset safety. They demonstrate proactive stewardship, instilling confidence in stakeholders, regulatory bodies, and the community at large.

Long-Term Savings and Benefits

Furthermore, the benefits of periodic updates extend beyond immediate safety concerns. They contribute to long-term cost savings and sustainability efforts. Accurate schematics facilitate strategic planning and resource allocation, enabling hospitals to identify areas for optimization and efficiency improvements. By preemptively addressing issues and mitigating risks, hospitals can avoid costly repairs, downtime, and potential liabilities down the line. Additionally, staying abreast of technological advancements such as digital CAD schematics and best practices, including this periodic updating of the schematics, ensures that hospital infrastructure remains adaptable to future challenges.

Next Step Actions

In conclusion, the periodic updating of piping schematics is not merely a best practice; it is a fundamental necessity in modern healthcare infrastructure management. By normalizing this practice, hospitals can reap a multitude of benefits, ranging from enhanced safety and reliability to improved operational efficiency and regulatory compliance. It’s time to shift the paradigm and recognize how critical updated schematics play in safeguarding the well-being of patients, staff, and the broader community. Let’s make the commitment to keep hospital piping schematics up to date, for the sake of a safer, more resilient healthcare environment for all.