Summary

- Promote a “Get-It-If-You’re-There” team approach to Service Line Material data collection.

- Cross-examine existing paper/data trails to reveal already documented locations of lead service lines.

- With a 2024 deadline looming, lean on specialty contractors and public awareness efforts.

Gaining access to water customers’ homes and having personal trained to be able to assess the service connection’s material, size, location, and conditions is a logistic and training hassle. One way to reduce the strain of this burden is to combine service line inventory activities into potentially already occurring onsite utility work, such as water meter changeout or cross-connection control inspections. This will lead to several benefits for the water utility: here’s how:

1. Efficiency While Onsite

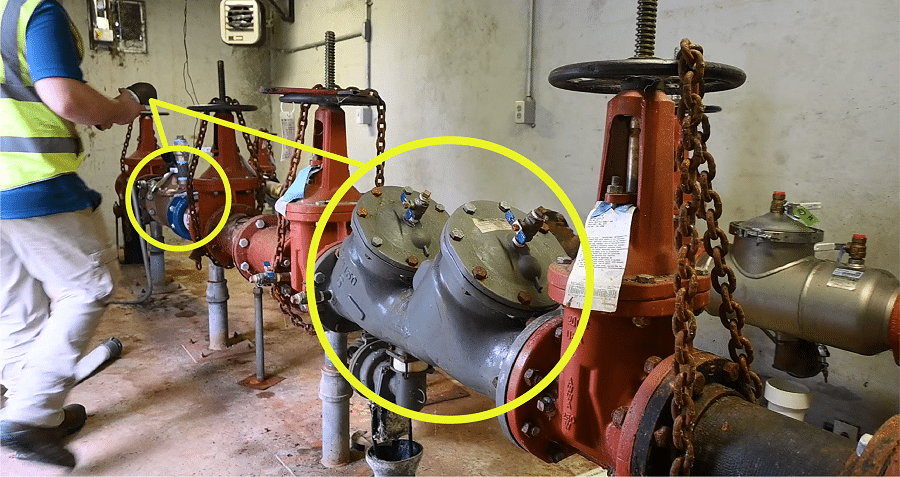

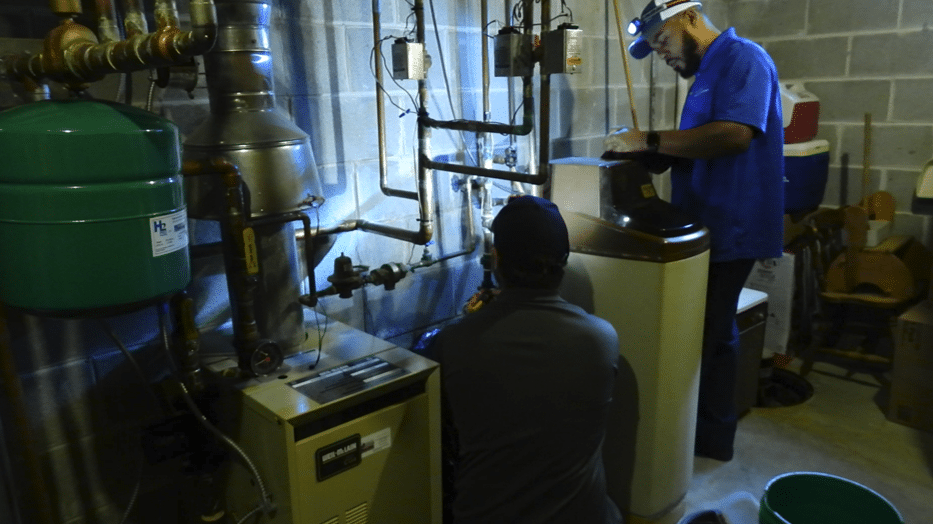

Efficiency is the cornerstone of any operation and making multiple trips out to a water customer’s residence for a meter changeout, a cross-connection control inspection, and a service line inventory triples the workload. By making one trip onsite, water utility staff is presented with a unique opportunity to gather comprehensive data efficiently. During meter changeouts or cross-connection control surveys, utility personnel are physically present at the service connections, allowing them to directly observe and record pertinent details without additional site visits. This eliminates the need for subsequent trips, saving both time and resources. Ideally, the meter changeout and cross-connection control inspection would also be completed at the same time; an all-in-one visit to reach compliance, mitigate risk, and equip the utility with knowledge.

“When we added the Service Line Material Assessment task to our current Cross-Connection Survey/Inspection activities, we nearly doubled our monthly target numbers in 2023” – Frank Samuelson

By capturing detailed information about service line materials, sizes, and locations during routine activities, utilities can streamline their data collection processes. This efficiency not only benefits the utility itself but also minimizes inconvenience to customers by reducing the frequency of service interruptions or visits by utility personnel. Moreover, having accurate and up-to-date data readily available ensures that decision-makers are well informed and can manage proactive maintenance and infrastructure planning.

2. Data Value and ROI for Future Projects

In addition to compliance requirements, capturing detailed information on existing service line materials and conditions plays a crucial role in planning for future projects and initiatives, particularly when beginning a program to remove and replace lead piping in the distribution system. Lead contamination in drinking water remains a significant public health concern, necessitating proactive measures to identify and address lead service lines.

Detailed records of service line materials, including the identification of lead components, enable utilities to create comprehensive inventories of lead service locations within their distribution systems. This information serves as a foundation for targeted lead service line replacement programs, helping utilities prioritize areas with the highest risk of lead exposure and allocate resources effectively.

Moreover, documenting the conditions and characteristics of service lines allows utilities to assess the scope of lead and copper piping projects accurately. Whether it involves partial replacements, full upgrades, or corrosion control measures, having a comprehensive understanding of existing infrastructure is essential for planning and budgeting purposes. By proactively addressing lead piping issues, utilities can safeguard public health, comply with regulatory requirements, and enhance consumer confidence in the quality of their drinking water.

3. Measurable Cost Savings Benefits

By completing a service line inventory while staff are already onsite for a meter changeout or a cross-connection control inspection, the utility can save money by not repeatedly sending employees out to the same location multiple times. By collecting a detailed inventory of service line materials and conditions before beginning a lead pipe replacement program, utilities can save money by only replacing those pipes that need to be replaced instead of replacing all service lines regardless of material or condition. These savings can be reinvested into other projects and programs for the water utility and bolster its reputation as an efficient and well-run operation serving the community.

A Doable Call to Action

By documenting service line materials, sizes, locations, and conditions while already onsite for other work, utilities can realize multiple benefits, ranging from operational efficiency to proactive planning for future projects. As utilities strive to optimize their infrastructure management practices and ensure the delivery of safe and reliable water services, meticulous data collection emerges as a foundational element of their operations. By leveraging comprehensive information obtained during onsite activities, utilities can make informed decisions, prioritize maintenance efforts, and address emerging challenges effectively. Ultimately, the commitment to capturing detailed information during meter changeouts and cross-connection control surveys underscores the utility’s dedication to excellence, resilience, and public health protection.