Making Lemonade is usually associated with summertime. Ensuring compliance and avoiding cross-connection and backflow “lemons” can be a year-round activity. Public Water System staff and decision makers typically have enough on their plate, day in and day out. From aging infrastructure, constrained budgets, and limited staffing resources, the last thing they need to contend with is non-compliance with Cross-Connection Control requirements. Receiving a non-compliance status often surprises water system leadership as a result of sanitary survey or backflow incident. Navigating state codes and regulations on this topic is akin to the age-old adage: when life hands you lemons, make lemonade! What kinds of lemonade can Water Utility Professionals make out of regulatory requirement lemons?

The Backflow Preventer Testing Lemon

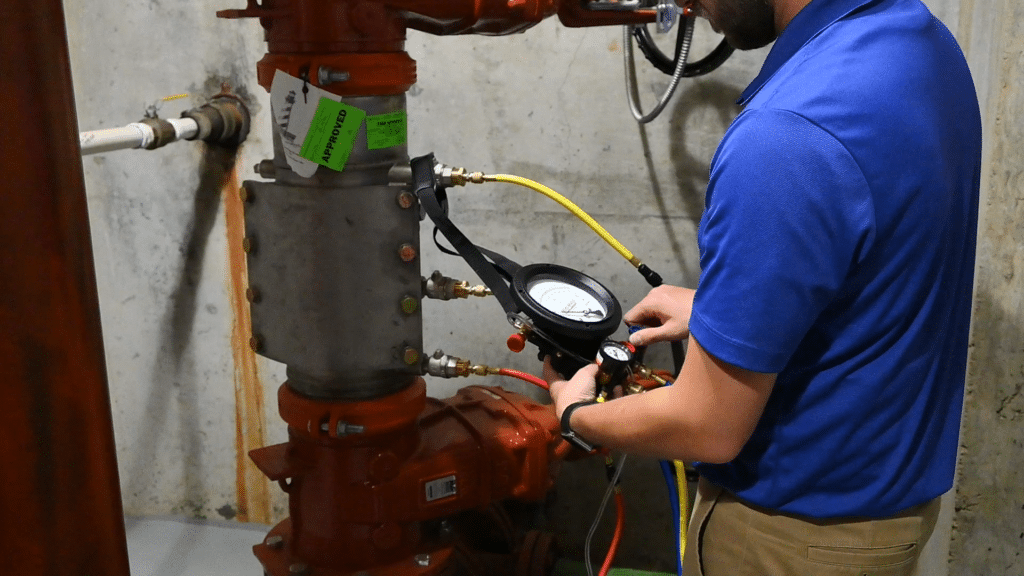

Backflow preventer assemblies, essential for safeguarding potable water from backflow contamination, require periodic testing and tracking for a reason: the intricate internal mechanics of the assembly can fail without any outward indication there is an issue. The regular testing mandated by these codes ensures that backflow preventers are functioning as intended. It’s a proactive measure that identifies potential issues that would otherwise go unnoticed, allowing for necessary repairs or replacements. This, in turn, minimizes the risk of backflow contamination, turning regulatory compliance into a recipe for lemonade by sweetening the reliability of these assemblies protecting the potable water supply.

Moreover, the enforcement of tracking facilitates comprehensive record-keeping, providing a transparent record of backflow preventers installed throughout the public distribution system. This record keeping also assists in keeping any periodic testing, annual or otherwise, up to date. In the case of a water contamination event or a regulatory audit, they also simplify the investigation process while also serving as a testament to the commitment to compliance.

The Survey/Inspection Requirements Lemon

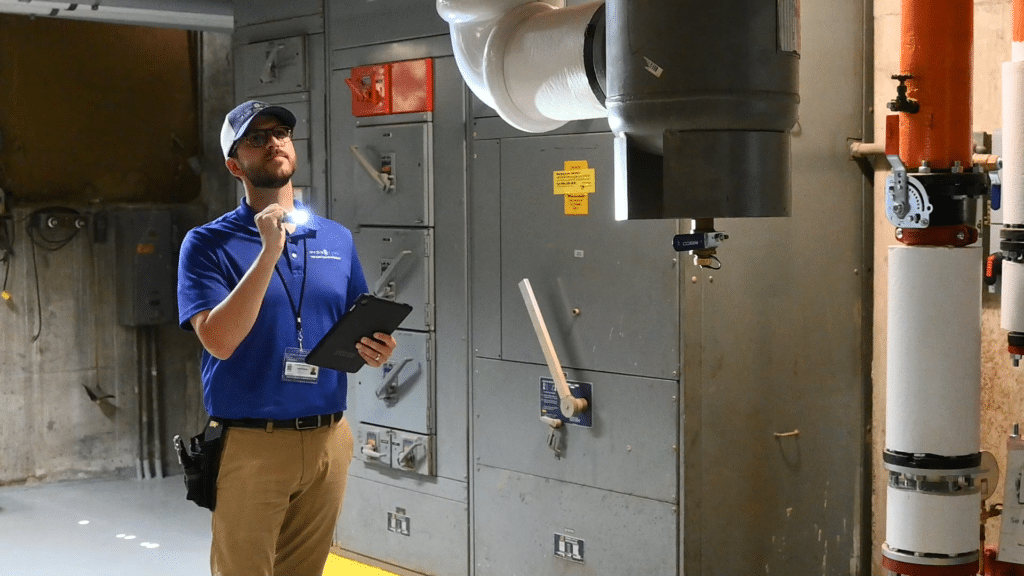

Regular surveys and/or inspections act as a vigilant eye on actual or potential cross-connections that could compromise water quality in the event of a backflow incident. Just like making lemonade out of life’s challenges, these boots-on-the-ground inspections identify and address issues proactively, preventing potential contamination. While the discovery of an unprotected cross-connection sounds like bad news, this discovery is actually a very positive development. Now that an issue has been identified, it can be resolved through the surveyor or inspector’s corrective action requirement, either eliminating or protecting the cross-connection. Without these onsite surveys, unknown issues could lurk in the piping system for years – until it is too late.

Furthermore, the comprehensive records generated through these inspections are like a sip of lemonade on a hot summer day, providing a refreshingly thorough history of cross-connection control measures and any actual or potential cross-connections and methods of backflow prevention onsite. In states that require annual reporting or in the case of a water quality incident, these records of activities and corrective action requirements show the hard work and dedication that the public water utility has invested into protecting the potable water supply.

The Annual Reporting Requirements Lemon

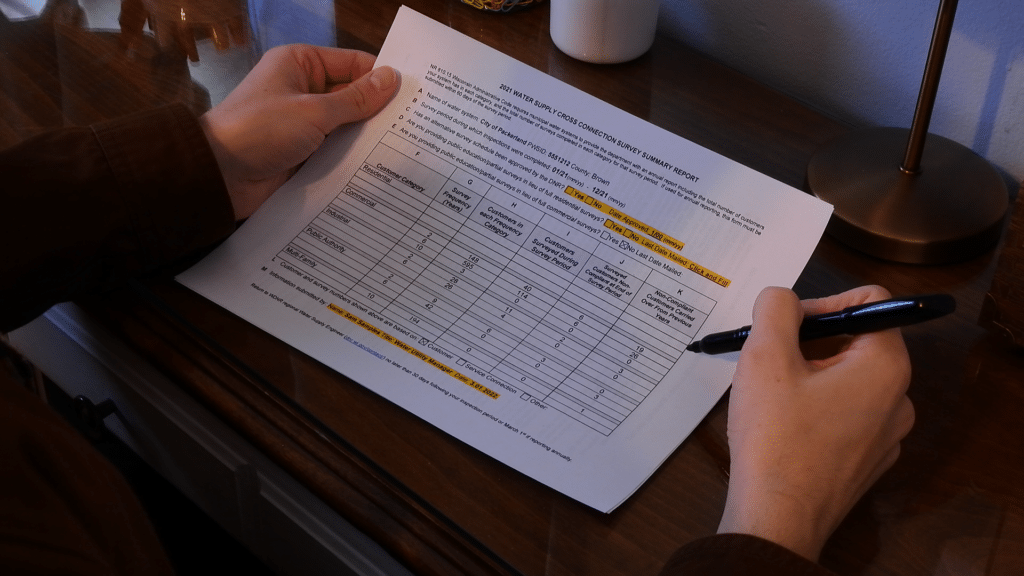

As briefly mentioned above, some states, such as Oregon, Wisconsin, Michigan and Florida, mandate the annual submission of a report to the state on the year’s Cross-Connection Control Program’s activities. Data could include the recent test records of known backflow preventers, number of devices successfully tested, or quantity of cross-connections discovered. The compiling of this information for reporting purposes becomes an opportunity to make lemonade out of lemons for public water systems and municipalities, as the process of compiling an annual report may seem arduous, it plays a crucial role in ensuring the transparency, accountability, and overall health of the water system.

The annual report submission is also a chance to showcase the utility’s commitment to excellence; not just to the state or other regulatory bodies, but to the water customers they serve. The documentation provides a clear record of the system’s performance, water quality standards, and compliance with regulatory measures. When state codes place the responsibility of annual reporting in the hands of Water Utility Professionals, it encourages a proactive approach to system management.

Compliance Lemonade

While dealing with the enforcement of backflow preventer test tracking, onsite cross-connection surveys, or annual reporting, remember the old saying: when life hands you lemons, make lemonade. Embracing the process ensures the functionality of crucial safety mechanisms, maintains transparent records, eliminated hazards to the public water distribution system, mitigates risks, keeps everyone accountable, and ultimately provides a refreshment for the health and safety of the community served by the water system or municipality.