Despite shifts in water safety regulations and advancements in cross-connection control, unprotected (and undetected) cross-connections still pose significant risks to public water systems, industrial facilities, and other commercial properties. These risks are not theoretical; they are real, reoccurring, and capable of causing severe contamination that compromises public health and business operations.

Cross-connections occur when potable water systems unintentionally connect with non-potable sources, allowing contaminants to flow into the drinking water supply. Without proper backflow prevention devices, hazardous substances such as chemicals, bacteria, and industrial waste can enter the system, creating a costly crisis that is difficult to remediate.

Why do these issues keep happening? The answer lies in complacency, oversight, and the assumption that once a cross-connection is addressed, it will never be a problem again. But, in reality, unprotected cross-connections are reoccurring by nature. Because they persist, what can public water system officials, industrial facility managers, and Environmental, Health, and Safety (EHS) departments do to prevent them?

Cross-Connection Control vs. Backflow Prevention: Key Differences & Essential Strategies

The Reoccurrence of Unprotected Cross-Connections

How do cross-connections occur—and, once remediated, occur again? Piping systems are dynamic. Whether in a public water system, a residential building, or a commercial facility, pipes are reconfigured, renovated, or updated to meet changing needs. And with those updates, cross-connections are often created (or recreated), putting the system at risk. The biggest culprits include:

- Lack of Program Oversight and Missed Inspections

Even with a cross-connection control program in place, extending gaps between periodic inspections can add to the problem of undetected hazards. As buildings age, plumbing modifications, new equipment installations, and operational changes introduce new risks that go unnoticed without on-site surveys and program updates. - Assumption of Compliance

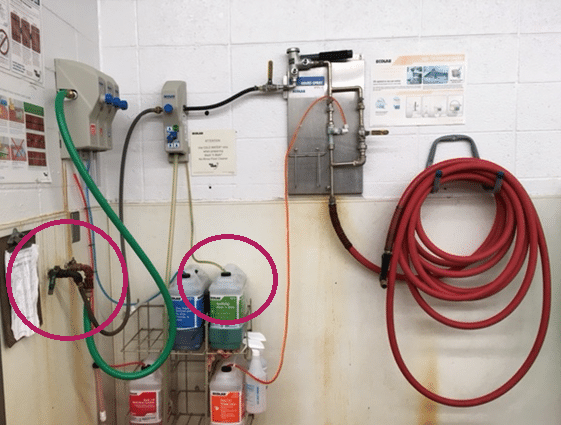

Many facility managers and public water system officials believe that, once a backflow preventer is installed, the problem is permanently solved. However, devices or assemblies can fail due to wear and tear, improper maintenance, or unauthorized removal. Without backflow testing and verification, these protective measures can become ineffective over time. - Lack of Awareness and Training

Maintenance staff often lack the necessary training to recognize cross-connections and understand their potential consequences. In many cases, cross-connections are unintentionally created during routine maintenance, renovations, or process modifications, increasing the risk of contamination.

Failing to control these cross-connections can result in:

- Public health threats from waterborne contaminants entering the drinking water system

- Costly compliance violations, legal liabilities, and regulatory penalties

- Production downtime and damaged reputations for industrial facilities

A single backflow incident can lead to widespread illness, expensive remediation efforts, and loss of trust in the water supply. Proactive prevention is not just recommended, it’s essential.

Key Takeaways for Water System Officials and Facility Managers

- Cross-Connection Control is Not One and Done

Ongoing inspections, record keeping, and routine testing of backflow prevention assemblies are essential to maintaining compliance and protecting public health. An annual or biennial cross-connection control survey should be a standard practice. - Invest in Training and Awareness Programs

Educating employees, facility operators, and maintenance personnel on cross-connection risks helps prevent contamination. Routine training sessions and visual guides have a significant impact in reducing risks at the source. - Enforce Strict Compliance with Testing and Maintenance Requirements

Backflow prevention assemblies should be tested at mandated intervals and replaced as needed. Industrial facilities should integrate cross-connection control checks into standard operating procedures to ensure ongoing protection.

Unprotected cross-connections are a reoccurring challenge that demand vigilance. Public water system officials, industrial facility managers, and EHS departments must take a proactive approach to monitoring, training, and maintaining backflow prevention measures. By prioritizing prevention, you can protect water quality, safeguard public health, and ensure compliance with regulatory requirements.

Ignoring these risks is not an option. Staying ahead of the problem is the only way forward.

Ready to learn more about how HydroCorp can support your public water system or commercial facility with cross-connection control programs, on-site surveys, and piping schematics?