For public water supply system managers, meeting compliance and controlling Cross-Connections plays a pivotal role in ensuring safe drinking water. Cross-Connections, where non-potable water can mingle with potable water in the event of Backflow, pose a significant risk to public health. State administrative codes will typically indicate requirements for Cross-Connection Control Programs; however, these requirements vary from state to state. It is important to remember that no Program is a “one-size-fits-all” solution. The water supplier should learn about the different types of Programs and the methods of application before deciding which type of Cross-Connection Control Program would be the right fit for their community. Two types of Programs that have emerged as the most common best practices are Containment Programs and Isolation Programs.

.

Cross-Connection Control Programs: The Essentials

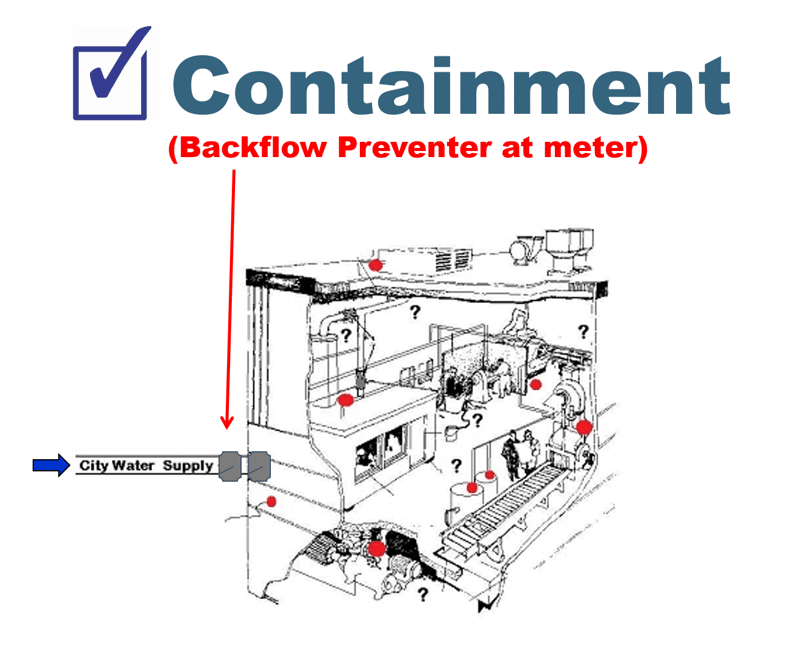

Containment Cross-Connection Control Programs

Containment Cross-Connection Control Programs focus on preventing contaminants from reaching the potable water supply distribution system by incorporating a Backflow Prevention Assembly as close to the service connection to the public water system as possible. These Assemblies ensure that, in the case of a backflow event, the potential contaminate or pollutant does not backflow into the distribution system.

Benefits of Containment Cross-Connection Control Programs

- Protection of the Public: One of the key advantages of Containment Programs is the protection of the public from Backflow events. In the event of a Backflow incident involving a dangerous and potentially deadly substance, Containment Programs keep that substance from entering the public water distribution system.

- Ease of Implementation: Implementing Containment Cross-Connection Control Programs is often less disruptive than Isolation methods. The installation of Backflow Prevention Assemblies is generally straightforward, requiring minimal changes to existing plumbing systems, and during onsite assessments, a quick and easy verification of the presence of the Assembly would be all that is necessary.

.

.

Shortcomings of Containment Cross-Connection Control Programs

- Dependent Upon Single Assembly: A Containment Program relies solely on a single Backflow Prevention Assembly at each building to keep the water supply safe. If any mechanical failures of the Assembly were to occur, the distribution system would be susceptible to any backflow contamination from the facility where the Containment Assembly had failed.

- Limited Scope: This type of Program does not eliminate any internal Cross-Connection hazards to the individual user’s water supply, leaving the internal supply and the occupants therein susceptible to the dangers of Backflow. This means that Backflow incidents within the building could still be harmful to anyone inside of that building.

.

.

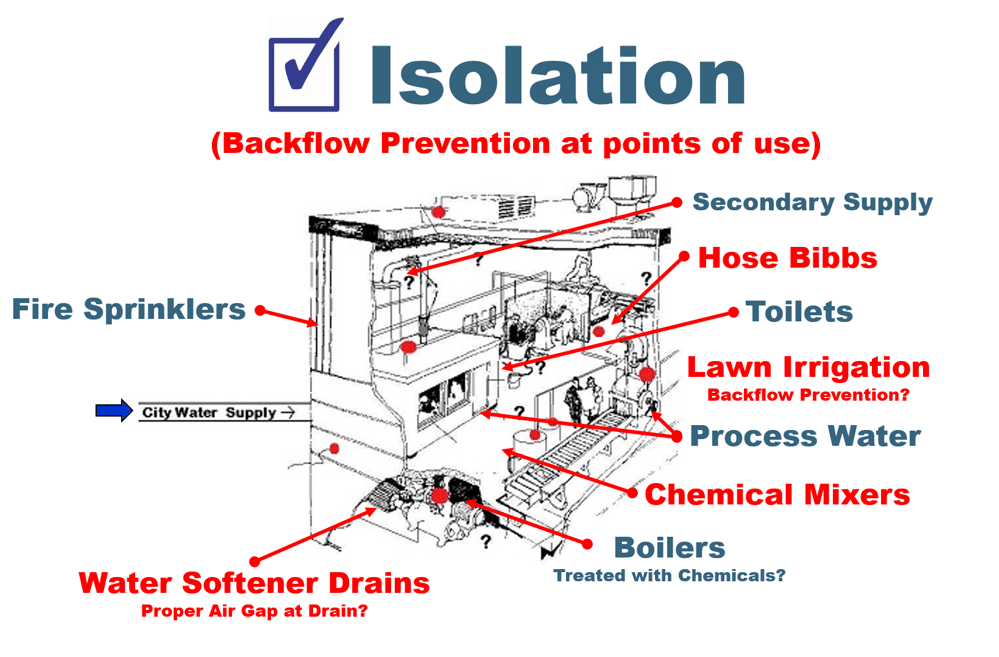

Isolation Cross-Connection Control Programs

Isolation Cross-Connection Control Programs take a different approach by focusing on eliminating or protecting each individual Cross-Connection itself at every point of use within the potable water piping system. This method involves onsite assessments of each and every connection to the potable water plumbing system to determine if proper Backflow Prevention methods are in place and, if not, to make corrective action requirements to bring the facility up to code.

Benefits of Isolation Cross-Connection Control Programs

- Comprehensive Protection: Most significantly, Isolation Programs offer more comprehensive protection by addressing Cross-Connections throughout a building or facility’s plumbing, which mitigates the risk of harm to the occupants of the building as well as the risk of a contamination event affecting the public distribution system. Containment Programs do not locate or eliminate any internal Cross-Connection hazards to the individual user’s water supply.

- Less Demanding on Water Customers: Unlike containment programs that rely on the installation and ongoing maintenance of a Backflow Prevention Assembly, Isolation Programs examine the levels of hazards to determine proper protection. This can result in lower long-term maintenance costs when it comes to non-industrial or manufacturing facilities, such as office buildings or retail stores where the only points of use are restrooms and exterior hose spigots. Instead of an expensive Containment Assembly that requires annual testing by a certified tester, these simple fixtures would only require affordable Anti-Siphon Ballcocks and Hose Bibb Vacuum Breakers.

.

.

Shortcomings of Isolation Cross-Connection Control Programs

- Complexity of Systems: The implementation of Isolation Programs is more complex and may require significant modifications to existing infrastructure depending on the existing Backflow Prevention methods in place and the degree of hazard of the facilities. Onsite water utility staff must methodically and carefully locate any and all connections to the public water supply system and determine if existing methods are up to code. Some Backflow Preventers may be camouflaged or in hard-to-reach places, such as above ceiling tiles or tucked away in a closet. This type of Program also relies heavily on Water Customer participation, as building managers or facility staff will need to assist the onsite water utility personnel in locating all points of use.

- More Demanding on Water Utility: Aside from requiring a well-educated on-site surveyor, the water utility will also need to bear the burden of information, as these detailed assessments carry far more intel than a simple Containment Assembly test form. Between hiring additional staff, purchasing data management software, and supervising the mailing of notifications for assessments to water customers, Isolation Programs do require more investment, effort, and attention to detail from the water utility.

.

Conclusion

Both Containment Cross-Connection Control Programs and Isolation Cross-Connection Control Programs can offer compliance with state administrative codes, depending upon the word of the law. The choice between these approaches depends on various factors, including the specific characteristics of the water distribution system, the nature of potential Cross-Connections, and available resources. However, it is imperative to acknowledge that Containment Only Programs simply do not provide protection for the inhabitants of a building or facility that experiences a Backflow Contamination incident. Without the insights provided from on-site assessments, hazardous Cross-Connections can exist out of sight and out of mind. The greatest way to protect water customers is by implementing an Isolation Program to discover the hidden dangers of unprotected Cross-Connections.