In the dynamic landscape of Industrial and Hospital facilities, the significance of correct piping labeling and schematics cannot be overstated. From preventing hazardous interconnections to ensuring regulatory compliance, these practices are paramount for safeguarding personnel, maintaining operational continuity, and upholding environmental and safety standards.

Take-Away’s of this article for Facility Infrastructure Managers:

Invest in Comprehensive Training Programs:

Prioritize training programs for personnel involved in maintenance, operations, and emergency response. Ensure they are well-versed in interpreting piping schematics and understanding the importance of accurate labeling. This investment in knowledge will empower teams to make informed decisions, reducing the risk of errors and enhancing overall facility safety.

Implement Regular Audits and Updates:

Establish a routine audit schedule to assess the accuracy of piping labels and schematics. Regular updates should be made to reflect any changes in the facility’s infrastructure. This proactive approach not only ensures ongoing compliance but also minimizes the likelihood of incidents caused by outdated or inaccurate information. Regular maintenance of documentation is as crucial as the maintenance of the physical systems themselves.

Avoiding System Outages:

In a power generation facility, a routine inspection identifies a potential issue with a critical cooling system. With accurate piping schematics, maintenance teams quickly locate and address the problem, preventing an unexpected system outage. This timely intervention ensures uninterrupted power generation and prevents financial losses associated with downtime.4

Regulatory Compliance:

Regulatory inspectors visit a manufacturing facility to ensure compliance with safety standards. The absence of proper pipe labeling and schematics results in citations and fines. Implementing accurate labeling and comprehensive schematics not only brings the facility into compliance but also helps maintain a positive relationship with regulatory authorities.

View this Example of a well-documented piping system HERE

Contamination Prevention:

In a pharmaceutical manufacturing facility, two pipelines containing different drug components run parallel. Due to unclear labeling, a technician mistakenly connects the wrong hose during a product changeover, leading to contamination. Accurate labeling would have prevented this error, ensuring the integrity of the pharmaceutical products.

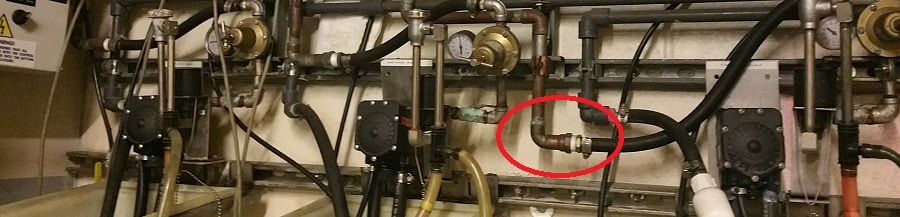

Preventing Interconnections:

In a chemical processing plant, two pipelines run in close proximity—one carrying a corrosive substance and the other a reactive chemical. Due to improper labeling, a maintenance worker mistakenly opens a valve connecting the two, resulting in a hazardous reaction. Correct labeling would have prevented this interconnection, avoiding the potential release of toxic fumes and ensuring worker safety.

Enhancing Emergency Response:

A fire breaks out in an industrial facility, and emergency responders need to shut off specific utility lines to contain the blaze. Clear piping schematics enable the responders to quickly locate and isolate the necessary valves, preventing the fire from spreading to other parts of the facility and minimizing potential environmental damage.

Mitigating Pipe System Failures:

During routine maintenance in a chemical plant, a maintenance technician misidentifies a pipe and selects the wrong valve for closure. This mistake leads to a sudden pressure surge, causing a pipe system failure. Accurate labeling would have guided the technician to the correct valve, preventing the failure and avoiding potential injuries.

Want more resources on how to improve your facility piping system label accuracy? Get the FREE Piping Systems E-Book HERE

GET THE FREE E-Book Guide HERE

Whether you are a facility manager, maintenance engineer, or aspiring professional in the field, this guide will equip you with the knowledge and tools to ensure your facility’s piping systems remain well-documented and easily navigable.