Key Takeaways:

- When emergencies with your piping infrastructure inevitably arise, there can be costs in the tens of thousands involved; but being prepared with accurate, up-to-date information can help mitigate these potential costs.

- By updating and maintaining schematics of your critical piping systems (including potable water and medical gases), you can avoid the costs and headaches of pipe bursts, mislabeled piping, or out of date schematics that lead your maintenance teams on wild goose chases.

- Download the 2024 Practical Guide to Piping Schematics by clicking HERE and find out how you can set yourself, your team, and your facility up for success!

The Practical Guide to Piping Schematics

As a manager or administrator of a Facility with critical piping infrastructure such as Hospital, School, or Manufacturing Facility, you pride yourself on keeping the people in your building safe. This includes protecting the integrity of your critical piping systems that convey potable water, medical gases, or other critical fluids or gases throughout the facility to serve employees, patients or processes. However, as if the daily monitoring and maintenance of your facility’s infrastructure wasn’t challenging enough, piping issues and emergencies are inevitable. Threats such as a legionella outbreak, contamination from cross-connections, or mechanical damage of your piping system can turn your already hectic day into a more challenging and demanding ordeal.

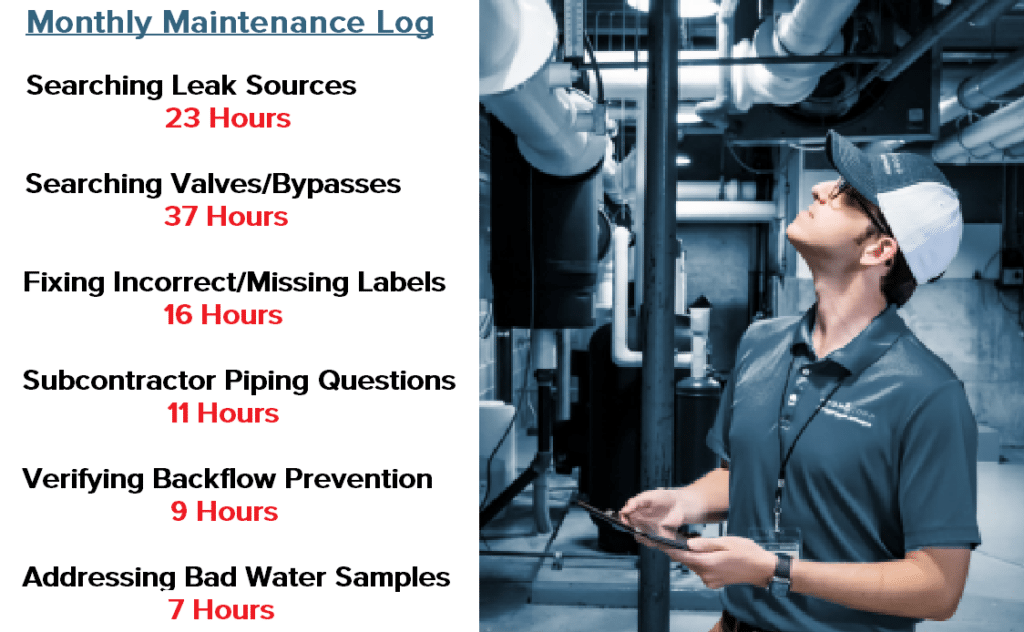

When you need to urgently address a problem in your building’s potable water system or track down an issue in your medical gas piping, are you stuck rifling through incomplete or out of date blueprints? Does it take costly hours for you or your staff to locate a leak with trial-by-error valve closures? Has your facility undergone any plumbing changes since its initial construction and creation of the original schematics? Having reliable piping schematics is not only helpful, it’s essential for effective system management, long-term cost savings, and supports efforts in complying with industry standards. Here are some potential problems and costs that can arise in emergency situations of your piping schematics are out of date:

The Cost of Emergency Repairs

Imagine the scenario: a leak develops in the medical gas piping or potable water plumbing. Emergency repairs become necessary, but that involves costly labor and material expenses. In the case of flooding and water damage, those costs can skyrocket. Moreover, the disruption to regular operations can be substantial, potentially affecting patient care. According to industry estimates, the cost of emergency repairs for such critical systems can easily run into tens of thousands of dollars, not to mention the intangible costs associated with potential delays in patient care and the resultant impact on the reputation of the healthcare facility.

Reputational Damage

When it comes to representing a successful healthcare brand, reputation is paramount. Any harm caused by procedural or infrastructural errors can tarnish the reputation built painstakingly over years. Incidents related to mislabeled or interconnected piping can attract unwanted media attention, further exacerbating the damage to the institution’s reputation. The cost of reputation loss, though difficult to quantify, can be staggering, affecting patient retention, referrals, and even staff morale. These potential catastrophes are avoidable if knowledge and information about these critical piping systems are documented and, if any issues are found during routine survey activities, corrected.

Potential Litigation and Regulatory Non-Compliance

In the event of an outbreak of Legionnaires’ disease or any loss of patient life attributed to incorrect medical gas usage, the financial repercussions can be staggering. Legal fees, settlement costs, and potential fines imposed by regulatory authorities can place a significant strain on the institution’s finances. Moreover, non-compliance with regulations pertaining to piping systems can lead to sanctions, jeopardizing the facility’s license to operate and further denting its reputation.

Long-Term Savings Through Proactive Measures

The key to mitigating these risks lies in proactive measures, chief among them being the updating and maintenance of your piping schematics. By investing in the creation and maintenance of accurate blueprints of the facility’s piping infrastructure, healthcare administrators like yourself will have a reliable and exact map of the entirety of their piping systems, including pipe diameter, gas/process flow direction existing and proposed pipe labels, shut off valves, check valves, pressure indicators, pressure regulators, filters, and more. This information will help prevent or mitigate emergency repair costs, downtime, and other issues that can be caused by a simple lack of information.

Enhancing Operational Efficiency and Safety

Beyond cost considerations, up-to-date piping schematics contribute to operational efficiency and safety. Clear and accurate documentation of the piping layout facilitates swift maintenance activities, enabling technicians to locate valves or address issues without delay. Moreover, detailed schematics aid in staff training, ensuring that personnel are well-versed in the intricacies of the facility’s infrastructure, thereby reducing the likelihood of errors and accidents.

Final Thoughts

The potential for long-term cost savings by commissioning and maintaining up-to-date piping schematics in healthcare facilities cannot be overstated. From mitigating the financial impact of emergency repairs to safeguarding your company’s brand and reputation and ensuring compliance with regulatory requirements, accurate blueprints of piping systems are indispensable assets. By prioritizing investment in the generation of as-installed, accurate piping schematics and in the routine re-surveying of piping systems to add any modifications or updates, healthcare administrators can enhance operational efficiency, mitigate risks, and, most importantly, uphold their commitment to patient safety and well-being.