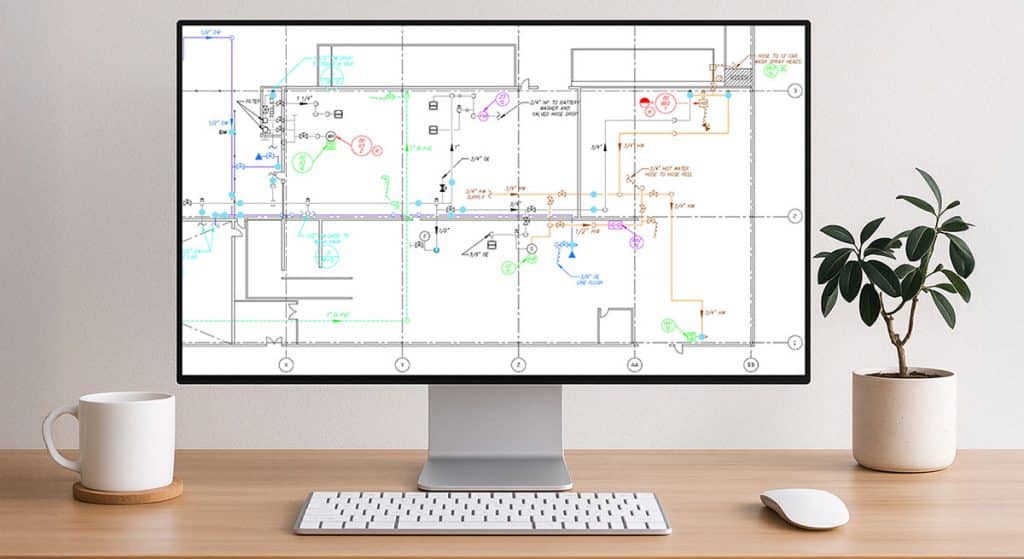

Reliable Piping Schematics for Every Facility

Know where your pipes go

Industrial and healthcare facilities have complex process piping systems that can make it difficult to stay on top of potential safety risks. And the dynamic nature of these facilities means the infrastructure and its needs frequently change: New functions and new capacities are added. Maintenance schedules get modified. Drawings and employee notes get misplaced. Accurate, up-to-date piping schematics provide you with the location of potential hazards, help you respond in an emergency, and ensure efficient operations.