Summary:

Sanitary surveys (performed by or for state regulators) are required periodically for public water systems in all 50 states. Individuals conducting these surveys are trained to identify hazards, ensure compliance, and recommend corrective actions. Questions surrounding your system’s cross-connection control program are bound to be posed during the survey – here are 5 tips for 5 categories of cross-connection control programs:

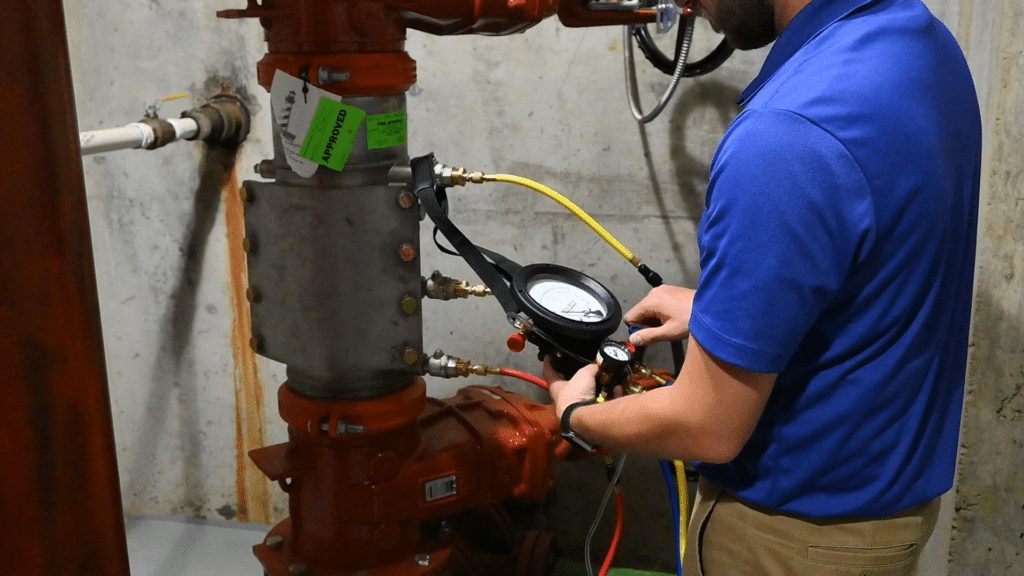

1. Backflow Preventer Test Record Data:

Potential Sanitary Survey Questions:

- Can you provide records of recent backflow preventer tests?

- How are backflow preventer testing records maintained and organized?

- What actions are taken in response to failed backflow preventer tests?

- Are backflow preventers repaired or replaced promptly when necessary?

- How do you ensure accuracy and completeness of backflow preventer testing records?

Proactive Actions:

- Keep detailed records of all backflow preventer tests, including testing dates, results, and any corrective actions taken.

- Implement a system for organizing and storing backflow preventer testing records in a centralized location.

- Develop clear protocols for addressing failed backflow preventer tests, including prompt repairs or replacements.

- Conduct regular audits of backflow preventer testing records to ensure accuracy and completeness.

- Provide training to staff responsible for maintaining backflow preventer testing records to ensure consistency and reliability.

2. Cross-Connection Control Program Activities:

Potential Sanitary Survey Questions:

- What is the status of your cross-connection control program?

- Can you provide documentation of your cross-connection control plan?

- How do you identify and assess potential cross-connection hazards?

- What measures are in place to mitigate cross-connection risks?

- How often are backflow preventers tested and maintained?

Proactive Actions:

- Maintain a comprehensive cross-connection control plan accessible to all staff.

- Conduct regular reviews and updates of the cross-connection control plan as needed.

- Perform routine inspections of the water distribution system to identify potential cross-connection hazards.

- Implement measures such as air gaps, reduced pressure zones, and double-check valves to mitigate cross-connection risks.

- Establish a schedule for regular testing and maintenance of backflow preventers in accordance with regulatory requirements.

3. Documentation of Cross-Connection Control Program:

Potential Sanitary Survey Questions:

- Can you provide documentation of your cross-connection control program, including policies, procedures, and protocols?

- How often is your cross-connection control plan reviewed and updated?

- Are cross-connection hazards identified and assessed regularly, and if so, how?

- What measures are in place to ensure compliance with cross-connection control regulations?

- How do you communicate cross-connection control requirements to relevant stakeholders?

Proactive Actions:

- Maintain detailed documentation of the cross-connection control program, including written policies, procedures, and protocols.

- Conduct regular reviews of the cross-connection control plan to ensure alignment with regulatory requirements and industry best practices.

- Implement a systematic approach to identifying and assessing cross-connection hazards, including routine inspections and risk assessments.

- Establish clear procedures for ensuring compliance with cross-connection control regulations, including training for staff and monitoring of program effectiveness.

- Communicate cross-connection control requirements to relevant stakeholders through training sessions, informational materials, and outreach efforts.

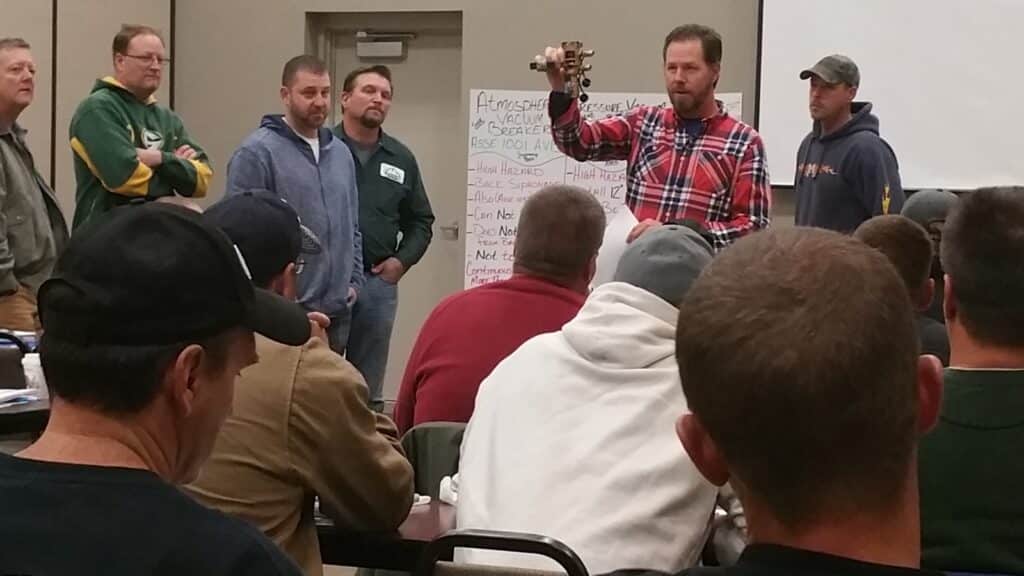

4. Training and Education on Cross-Connection Control:

Potential Sanitary Survey Questions:

- How do you train staff on cross-connection control procedures and requirements?

- Are employees responsible for cross-connection control activities adequately trained and certified?

- What measures are in place to ensure ongoing education and awareness of cross-connection control among staff?

- How do you educate customers and stakeholders about cross-connection control and their role in preventing contamination?

- Can you provide documentation of staff training and education initiatives related to cross-connection control?

Proactive Actions:

- Develop comprehensive training programs for staff involved in cross-connection control activities, covering topics such as identification of hazards, proper installation and maintenance of backflow preventers, and regulatory compliance.

- Ensure that employees responsible for cross-connection control activities receive appropriate certifications and credentials, such as backflow prevention certification.

- Implement ongoing education and awareness initiatives to keep staff informed about changes in regulations, emerging issues, and best practices related to cross-connection control.

- Engage with customers and stakeholders through outreach efforts, workshops, and informational materials to raise awareness about the importance of cross-connection control and encourage compliance with program requirements.

- Maintain documentation of staff training and education initiatives, including attendance records, training materials, and evaluations of training effectiveness.

5. Auditing and Continuous Improvement of Cross-Connection Control Program:

Potential Sanitary Survey Questions:

- How do you monitor the effectiveness of your cross-connection control program?

- Are audits conducted regularly to assess compliance with cross-connection control regulations and program requirements?

- What measures are in place to address deficiencies identified during audits or inspections?

- How do you track and implement recommendations for improvement in the cross-connection control program?

- Can you provide documentation of recent audits and improvement initiatives related to cross-connection control?

Proactive Actions:

- Establish monitoring and evaluation mechanisms to assess the effectiveness of the cross-connection control program, including key performance indicators, metrics, and benchmarks.

- Conduct regular audits and inspections of cross-connection control activities to identify areas for improvement and ensure compliance with regulatory requirements.

- Develop protocols for addressing deficiencies identified during audits or inspections, including corrective actions, follow-up procedures, and tracking of recommendations.

- Implement a process for tracking and implementing recommendations for improvement in the cross-connection control program, including assigning responsibilities, setting timelines, and monitoring progress.

- Maintain documentation of audit findings, corrective actions, and improvement initiatives related to cross-connection control, including audit reports, action plans, and progress reports.

Take Aways

By addressing these key questions and implementing proactive actions related to backflow preventer test record data and cross-connection control program activities, public water systems can demonstrate their commitment to safeguarding the integrity of the water supply and protecting public health.