Piping systems are the lifeblood of many industrial, commercial, and residential environments. Whether transporting potable water, medical gases, or process fluids, these networks must be clearly and accurately labeled to ensure safety and efficiency. Incorrectly labeled pipes can lead to disastrous consequences, from health hazards to operational failures. This article explores the specific dangers associated with mislabeling these different types of fluid systems and underscores the importance of proper pipe identification.

Potable Water Systems

Health Risks

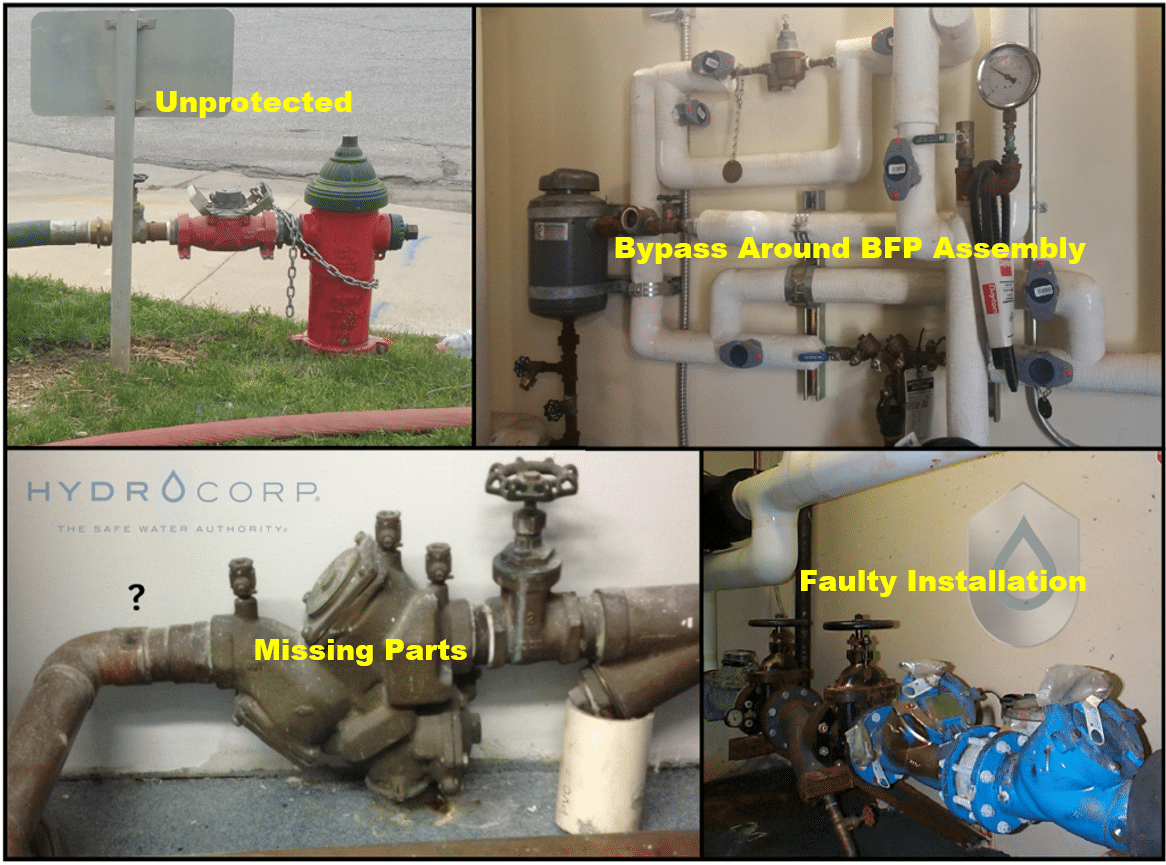

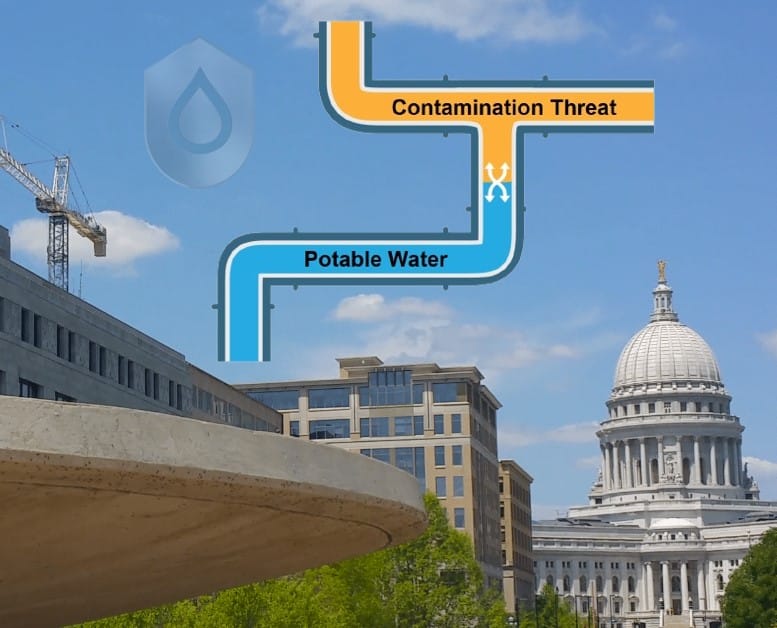

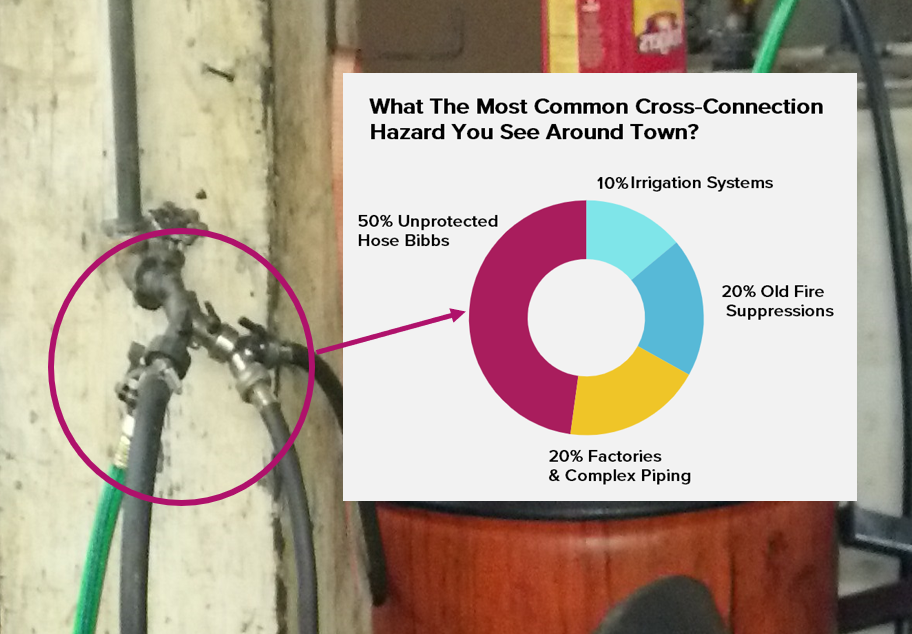

Potable water is intended for human consumption, cooking, and hygiene. Mislabeling these pipes can lead to severe health risks. For instance, if potable water pipes are mislabeled as non-potable or vice versa, there can be cross-contamination. Non-potable water often contains bacteria, chemicals, or other harmful substances that, if ingested, can cause gastrointestinal illnesses or more severe health conditions. Ensuring that potable water systems are accurately labeled prevents accidental consumption of contaminated water.

Compliance and Legal Issues

Incorrect labeling of potable water systems can lead to non-compliance with health and safety regulations. Agencies like the Environmental Protection Agency (EPA) and local health departments have stringent guidelines for public potable water quality. Non-compliance can result in hefty fines, legal action, and damage to a utility or company’s reputation. Proper labeling ensures adherence to these regulations, safeguarding public health and avoiding legal repercussions.

Medical Gas Systems

Patient Safety

Medical gas systems, which include oxygen, nitrous oxide, and medical air, are critical in healthcare settings. Incorrectly labeled medical gas pipes can lead to catastrophic outcomes. For example, delivering the wrong gas to a patient can result in severe injury or death. In one tragic instance, a hospital in Australia mistakenly connected nitrous oxide to a neonatal unit instead of oxygen, leading to the deaths of several newborns. This highlights the absolute necessity of precise labeling in medical gas systems.

Operational Efficiency

In a medical emergency, time is of the essence. Healthcare professionals must be able to identify the contents of gas lines quickly and accurately. Mislabeling can cause delays as staff double-check connections, potentially compromising patient care. Proper labeling enhances operational efficiency, ensuring that the right gas is delivered promptly and safely.

Non-Potable Water Systems

Environmental Contamination

Non-potable water is used for irrigation, industrial processes, and cooling systems. These systems often contain chemicals or contaminants that can cause environmental damage if misdirected. For instance, if non-potable water is mislabeled as potable and used for irrigation, harmful chemicals can leach into the soil, affecting plant life and potentially contaminating groundwater supplies. Proper labeling helps prevent environmental contamination and promotes sustainable water management practices.

Safety Hazards

Incorrect labeling can also pose direct safety hazards. For example, non-potable water used in cooling systems may contain biocides or antifreeze agents. If these pipes are mislabeled and connected to potable water systems, there is a risk of chemical ingestion, which can cause poisoning. Ensuring clear and accurate labeling mitigates these risks and protects both human health and the environment.

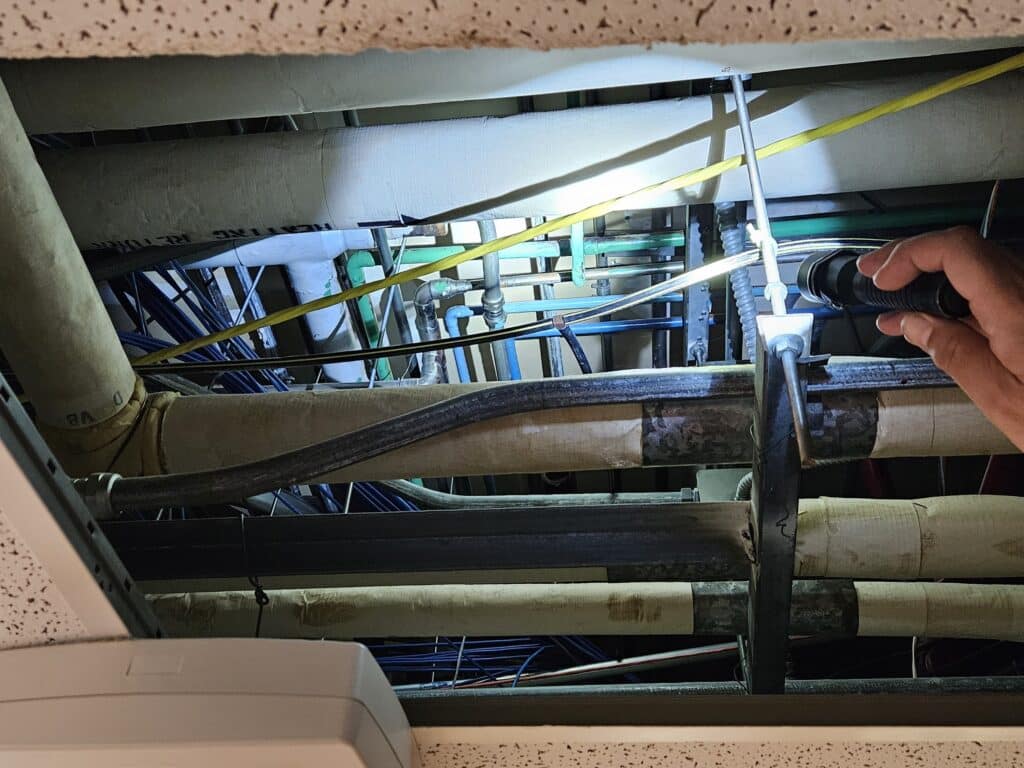

Process Fluid Lines

Process fluid lines transport a wide variety of substances, including chemicals, oils, and gases, essential for manufacturing and industrial processes. Incorrect labeling of these lines can lead to dangerous chemical reactions, fires, or explosions. For example, mixing incompatible chemicals due to mislabeled pipes can result in hazardous reactions, putting workers at risk and potentially causing extensive property damage.

Equipment Damage

Mislabeling can also lead to significant equipment damage. If a line intended for a specific chemical is mislabeled and connected to equipment designed for another substance, it can cause corrosion, blockages, or mechanical failures. This not only results in costly repairs and downtime but also poses safety risks to personnel operating the machinery. Accurate labeling is crucial to maintaining equipment integrity and operational continuity.

Best Practices for Labeling Piping Systems

Given the serious risks associated with incorrectly labeled piping systems, it is essential to adopt best practices for labeling. Here are some key recommendations:

Standardized Labeling

Implementing standardized labeling systems, such as those recommended by the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO), ensures consistency and clarity. These standards often use color codes, text, and symbols to indicate the contents and flow direction of pipes, making them easily recognizable.

Regular Inspections

Conducting regular inspections and audits of piping systems can help identify and correct labeling errors. This proactive approach allows for early detection of potential issues before they result in accidents or regulatory non-compliance.

Staff Training

Proper training for personnel on the importance of accurate labeling and how to read and interpret labels is crucial. Educated staff are more likely to follow protocols and report any discrepancies they encounter, further ensuring the integrity of the labeling system.

Use of Durable Materials

Labels should be made from durable materials that can withstand the environmental conditions of the piping system. For instance, labels in outdoor or industrial settings should be resistant to weather, chemicals, and abrasion to maintain legibility over time.

Digital Tracking Systems

Incorporating digital tracking and labeling systems can enhance accuracy and efficiency. These systems can include barcodes or QR codes that link to detailed information about the pipe contents, maintenance history, and safety protocols. Digital systems provide a comprehensive and easily accessible record, reducing the risk of human error.

Wrap Up

The hazards of incorrectly labeled piping systems are significant and varied, affecting everything from public health and patient safety to environmental protection and industrial operations. Accurate and consistent labeling is not merely a regulatory requirement but a fundamental aspect of safe and efficient system management. By adopting best practices and fostering a culture of safety and vigilance, organizations can mitigate these risks and ensure the reliable operation of their fluid systems.